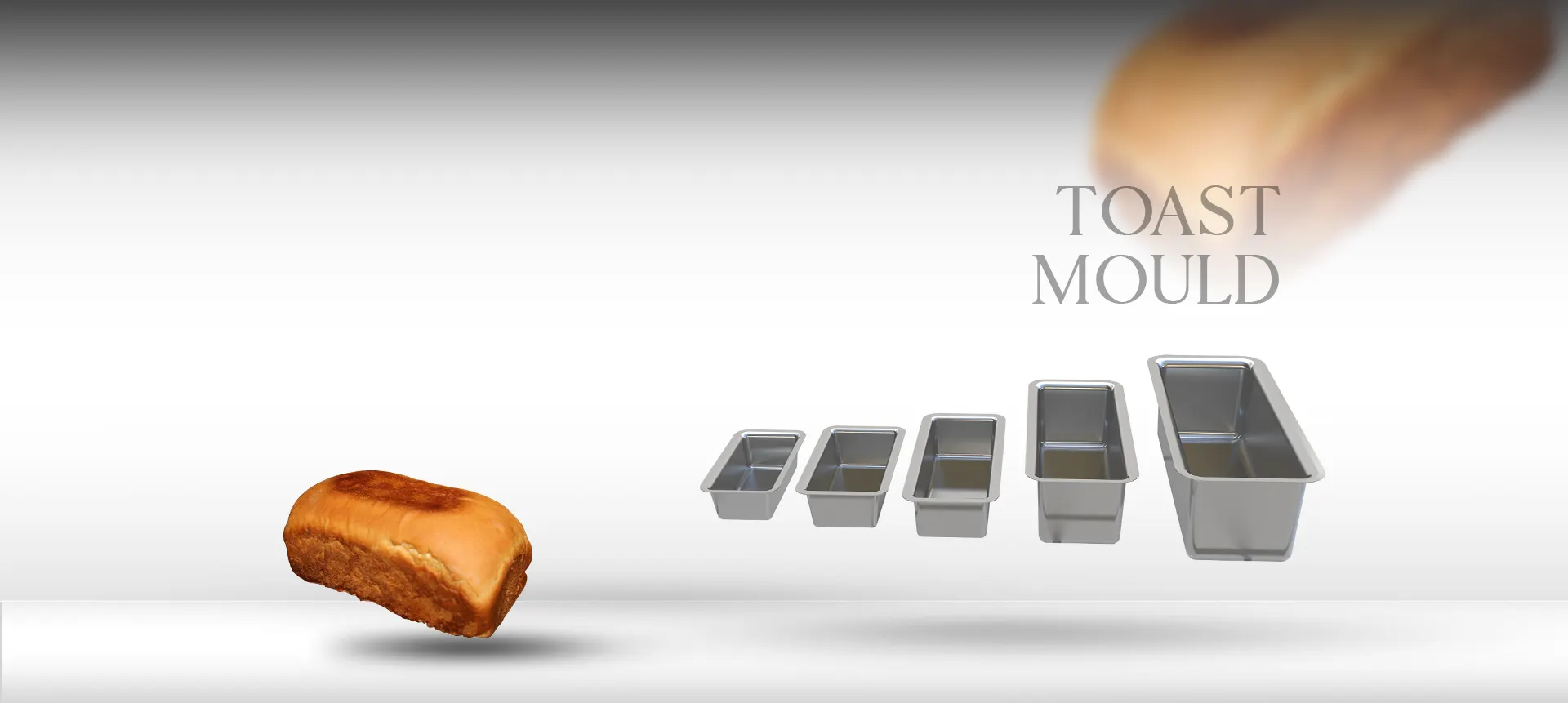

Toast Mould, also known as loaf pans, are among the most widely used baking molds for producing loaf and semi-loaf breads. They are manufactured in rectangular shapes from heat-resistant metals, with or without lids, as single units or in multi-unit configurations (gang molds), and in various dimensions. Toast Mould are primarily used for baking various types of toast bread and, in some cases, for producing croutons.

Types of Toast Mould

Lidded Toast Mould

Lidded toast bread pans are among the best and most common types used for baking toast bread. The lid ensures that the bread bakes into a uniform, rectangular loaf with a well-developed interior, resulting in superior appearance and baking quality.

Oiled Steel Toast Mould

Oiled steel toast bread pans, also known as black steel loaf pans, are a popular type made from drawn steel sheets and produced as a single, pressed piece. Due to their integrated structure and durable material, these pans offer high durability and efficiency and are highly suitable for baking high-quality toast bread. Initially, the toast pans are coated with non-edible oil and heated in the oven to prevent dough from sticking and to protect against rust.

Teflon-Coated Toast Mould

Teflon-coated toast bread pans are essentially oiled steel toast pans with a Teflon coating. Teflon is a non-stick coating applied to various surfaces, including metals, to prevent materials from adhering. Teflon toast pans are highly regarded due to their non-stick properties, which facilitate easy cleaning, and for producing uniform baking results.

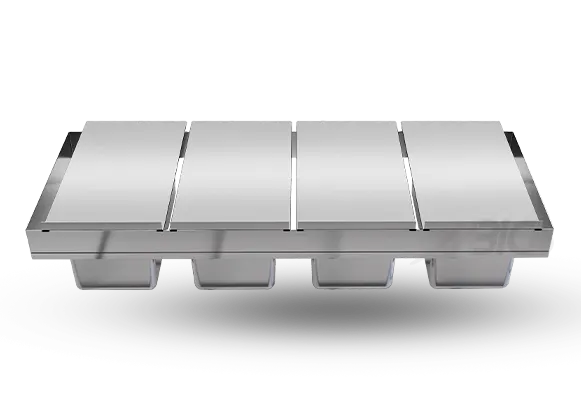

Gang Toast Mould

Gang toast bread pans consist of multiple interconnected pans that function as a single unit. This design allows the pans to be placed in the oven simultaneously and heated uniformly, resulting in consistent and even baking. Due to their interconnected structure, gang molds occupy less space and are easier to handle and transport.

Features of Toast Mould

- High thermal resistance

- Long lifespan and hygiene

- Uniform heat distribution

- Non-stick surface

- Variety in size and shape

- Easy cleaning

- Corrosion resistance

- Customizable dimensions

Toast Bread Pan Models and Technical Specifications

At Mashhad Baking Industries Company, toast pans are manufactured by welding, pressing, and as single units or in gang configurations (3 and 4 units) from oiled steel (black steel) in various sizes according to customer specifications.

MBI 50 gr

Internal Dimensions (cm):

2.9*5.1*11.3

External Dimensions (cm)

3*7*13

Sheet Thickness (mm)

0.8

Steel ST14

MBI 75 gr

Internal Dimensions (cm)

3.4*6*12.5

External Dimensions (cm)

3.5*8*14.5

Sheet Thickness (mm)

0.8

Steel ST14

MBI 110 gr

Internal Dimensions (cm)

3.7*6.5*16.5

External Dimensions (cm)

3.8*8.5*18.5

Sheet Thickness (mm)

0.8

Steel ST14

MBI 350 gr

Internal Dimensions (cm)

4.9*9*25

External Dimensions (cm)

5*11*27

Sheet Thickness (mm)

0.8

Steel ST14

MBI 450 gr

Internal Dimensions (cm)

9.5*10*22

External Dimensions (cm)

9.5*12.5*24.5

Sheet Thickness (mm)

0.8

Steel ST14

MBI 900 gr

Internal Dimensions (cm)

11.5*12*28.5

External Dimensions (cm)

11.5*14.5*30.5

Sheet Thickness (mm)

0.8

Steel ST14

Price and Warranty

To inquire about Toast Mould prices and receive pre-purchase consultation, please contact our sales experts through the provided contact methods.

Online Chat

24/7 Customer Support

We are ready to assist you 24 hours a day, 7 days a week.

In-Person Visit (Office/Factory Locations)

Factory: Mashhad, Asiaei Highway, Km 22, Beginning of Mohammadabad Ghaem Magham Road

Head Office: Mashhad, Malekolshoara Bahar St., Between Bahar 12 and 14, No. 579

Phone Calls (Contact Numbers)

Factory:

+985132464090

Head Office:

+985138583180

Get in Touch

To receive consultation and connect with our sales experts, please submit your request through the form below.

mbi@mbico.com

Frequently Asked Questions (FAQs) about Toast Mould

Toast pans are manufactured in two primary construction methods: pressed and welded. They are available in various types, including: Oiled steel (black steel) toast pans, lidded toast pans, Teflon-coated toast pans, small toast pans, large toast pans, and square toast pans.

A gang toast bread pan is created by connecting multiple individual toast pans together. This configuration facilitates easier and faster handling and transportation of the pans and also ensures more uniform baking.

Based on industry standards, toast bread is produced in the following sizes, corresponding to pan dimensions:

- 50-gram toast pan

- 75-gram toast pan

- 110-gram toast pan

- 350-gram toast pan

- 450-gram toast pan

- 900-gram toast pan

Before the first use, the oiled steel toast pan should be seasoned. This process involves coating the pan with non-edible oil and then baking it in the oven at a high temperature. This process creates a protective layer that prevents dough from sticking and helps to protect the pan from rust.