The Dough Rolling Machine is a vital and practical tool for Dough Forming. It can roll and sheet dough to various diameters and thicknesses, specifically designed for producing baguettes, demi-baguettes, sandwich bread, shirmal (a slightly sweet flatbread), Barbari, and other loaf breads. This machine plays a fundamental role in producing diverse, high-quality products and minimizes manual handling, thus improving quality and increasing production speed.

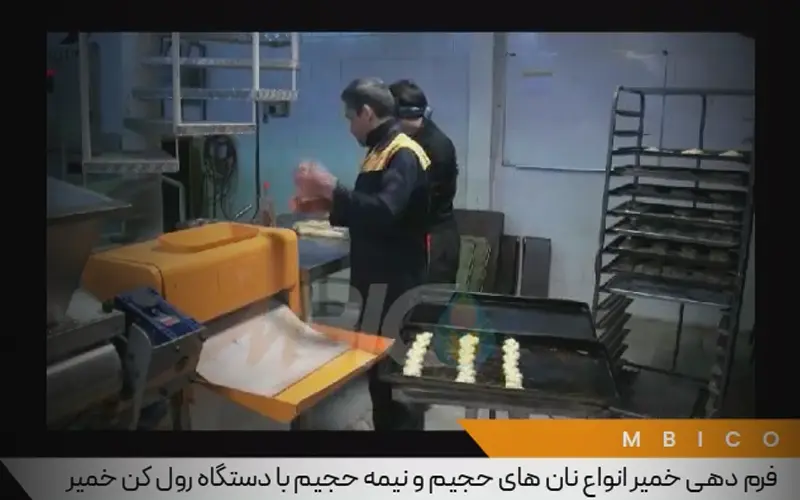

Rolling Machine is useful and practical Machine for dough forming for Baguette, Sandwich, Barbari Breads. In Industrial Bakeries, Rolling Machine is placed after Dough Rounder and dough is transferred by means of Conveyor Belt to the Rolling Machine.

Given its versatile applications, the dough roller is known by various names among users, including: fancy dough roller, sandwich dough roller, Barbari dough roller, and baguette dough roller. Using a dough roller leads to greater precision and consistency in bread production, significantly boosting production speed and efficiency.

Use of the Dough Roller in Producing Loaf and Fancy Breads

In industrial baking, the dough roller can be used in conjunction with other equipment to not only improve the quality and uniformity of the final products but also to enhance productivity and reduce production time. In such setups, the dough roller is typically positioned after dividers or rounders, allowing the portioned dough to be conveyed directly to the roller via a conveyor belt for shaping

Using a dough roller in producing loaf and fancy breads improves the uniformity of shape and size, enhancing the final product's quality. By reducing manual handling, the roller enhances hygiene and increases production speed. Precise adjustments of dough dimensions and weight allow for greater variety in fancy bread production, helping bakeries offer their products more efficiently.

Use of the Dough Roller in Producing Traditional Breads Like Barbari

In Barbari bread production, the most important step after dough preparation is uniform sheeting to achieve the proper thickness and consistent quality. In both traditional and industrial bakeries, the dough roller can facilitate this process. Using rollers, the machine sheets the dough precisely to the desired size and thickness without manual intervention, enabling bakers to produce high-quality, uniform Barbari bread at high volumes and faster speeds.

Factors to Consider When Choosing a Dough Roller

To select the best dough roller for both small and large bakeries, consider the following factors:

Thickness Adjustment

Price and Budget

Roller Type and Quality

Ease of Use and Maintenance

Brand and Warranty

Installation and Setup

Features and Advantages of the Dough Roller

- Shapes various types of dough

- Durable, wear-resistant rollers with a long lifespan

- Adjustable diameter and length of the output dough

- Equipped with wheels for easy mobility

- Available in single-phase and three-phase models

- One-year warranty and 10 years of after-sales service

- Meets Iranian national standards

- ISO 9001 certified

Price and Warranty

To inquire about the price of the industrial dough roller and for further information regarding the dough roller machine, you can contact our expert team through the following communication channels:

Online Chat

24/7 Customer Support

We are ready to assist you 24 hours a day, 7 days a week.

In-Person Visit (Office/Factory Locations)

Factory: Mashhad, Asiaei Highway, Km 22, Beginning of Mohammadabad Ghaem Magham Road

Head Office: Mashhad, Malekolshoara Bahar St., Between Bahar 12 and 14, No. 579

Phone Calls (Contact Numbers)

Factory:

05132464090

Head Office:

05138583180

Get in Touch

To receive consultation and connect with our sales experts, please submit your request through the Email below.

mbi@mbico.com

Frequently Asked Questions about the Dough Roller Machine

It is perfectly suited for fancy bakeries, Barbari bread bakeries, and confectioneries.

Yes, the Dough Roller allows for thickness adjustment of the dough.

The Dough Roller is suitable for shaping various types of dough, including dough for loaf breads such as baguettes, demi-baguettes, sandwich loaves, shirmal bread, and Barbari bread. It can also be used for pastry dough and specialty breads, such as thinning dough for herb and cheese bread.

The Dough Roller is equipped with caster wheels for easier movement and installation.

It is known by various names, including: Fancy Dough Roller, Barbari Dough Roller, Fancy Bread Dough Roller, Sandwich Bread Dough Roller, Baguette Dough Roller, and Fancy Bread Dough Roller.

It can handle dough for small sandwich rolls with a width of 15 cm up to large breads with a width of 60 cm.

At Mashhad Baking Industries, the Dough Roller is produced in two models based on customer needs: a single-phase Dough Roller and a three-phase Dough Roller

It comes with a one-year warranty and lifetime after-sales service