Articles

10 Future Technologies for the Food and Baking Industry

Bridging Artistry and Industry: Maintaining Quality in Large-Scale Professional Baking

Greetings to my colleagues and all who cherish the perfect aroma and texture of fresh bread. I approach this discussion from a unique vantage point: I am a seasoned baker who has felt the warmth of the dough firsthand, but also an engineer capable of designing the complex mechanics of a fully automated production line.

This dual expertise—combining ancestral knowledge with technical precision—is essential in modern professional baking. Years ago, as our small family business faced the inevitable challenges of significant growth, I realized a profound truth: maintaining consistent, high-quality output at a large scale is impossible without strategic reliance on robust technology.

This pressing concern—the need to marry artisanal heart with industrial precision—led me down a path that culminated in a strategic partnership with the esteemed Mashhad Baking Industries (Mbico). Choosing their industrial tunnel and deck ovens was not merely a purchase; it was a foundational investment built on their proven expertise, guaranteed quality, and dependable after-sales service.

Today, I want to share the specialized experience I have gained navigating this high-stakes transition. This report goes beyond a simple story of scaling up; it is a critical narrative detailing how, by successfully integrating the art of traditional baking with the science of modern engineering, we can achieve flawless product consistency and superior output. Our ultimate goal is always to produce bread that flawlessly embodies both the heart of the artist and the uncompromising precision of the machine, utilizing modern, reliable tools.

The Science of Superior Dough

1- Mastering Dough with Enzymes and Bio-Additives

In the past, our options for improving bread quality were limited to a few chemical additives whose names on the packaging worried customers. Today, however, we have an army of invisible artisans at our disposal: enzymes. These natural catalysts allow us to control the texture, shelf life, and flavor of bread with unprecedented precision and a “Clean Label.”

The Science of Enzymes in Action:

- Amylase: This enzyme is the champion in the fight against staling. Amylases, especially maltogenic amylases, break down damaged starches in the flour into simpler sugars. This process has two key benefits: first, it provides readily available food for the yeast, resulting in better and faster oven spring. Second, and more importantly, by altering the structure of starch molecules, it delays the retrogradation process, which is the main cause of bread hardening and staling.

- Xylanase: Also known as hemicellulase, this enzyme is a specialist in water management within the dough. Flour contains compounds called pentosans, which absorb large amounts of water, making the dough sticky and difficult to handle in industrial machinery. Xylanase breaks down these compounds, releasing the trapped water and resulting in a softer, more flexible, and more machinable dough, which ultimately leads to greater bread volume.

- Lipase: Lipase is nature’s emulsifier. This enzyme converts the fats present in flour into natural emulsifiers. These new compounds strengthen the gluten network, increase dough stability, and create a uniform texture with a soft and tender crumb. Using lipase allows us to remove chemical additives like DATEM from our formulations and offer a product with a cleaner label to the market.

- Protease: Sometimes we need to slightly weaken the gluten network, for example, in the production of biscuits and crackers where the dough needs to spread. Protease accomplishes this by controllably breaking down protein bonds, making the dough more flexible.

The “Clean Label” Revolution is a Market Strategy

At first glance, replacing a chemical with an enzyme might seem like a mere technical improvement. But the reality is deeper. Today’s consumers are more concerned than ever about their health and the ingredients in their products. They read labels and are wary of complex chemical names. Using enzymes empowers us to produce a product with a shorter, more natural, and more understandable ingredient list. This is a powerful competitive advantage. When you can proudly declare that your bread is “free from chemical additives,” you are aligning your product with one of the most important values of the modern consumer. This is a smart business decision that technology (the use of enzymes) directly enables.

My Experience: We created our own proprietary improver by combining specific percentages of these enzymes. The result was astonishing: the shelf life of our sandwich bread increased from 3 to 5 days, and the problem of dough stickiness in our dividers and moulders was almost eliminated, which meant fewer production line stoppages and increased efficiency.

2- Industrializing Sourdough and Long Fermentation

Sourdough is not just a flavor; it’s a philosophy. A philosophy of patience, symbiosis, and extracting the deepest flavors from the simplest ingredients. In the past, this process was artistic and unpredictable. But today, science has helped us to implement this art on an industrial scale with repeatable quality.

The Science of Long Fermentation in Action:

- Difference Between Traditional and Industrial Sourdough: Traditional sourdough relies on a symbiotic culture of wild yeasts and lactic acid bacteria present in the environment and flour. This process is highly dependent on environmental conditions. In contrast, industrial methods use “controlled starters.” These starters contain specific, cultivated strains of bacteria (like Lactobacilli) and yeasts (like Saccharomyces) that ensure predictable and uniform performance.

- Benefits of Slow Fermentation:

- Flavor and Aroma Development: During the long fermentation process (12 to 48 hours), lactic acid bacteria produce organic acids like lactic and acetic acid. These acids impart a complex, deep, and slightly tangy flavor profile to the bread that is never found in fast-fermented industrial breads (1 to 3 hours).

- Improved Digestibility: One of the greatest benefits of sourdough is the breakdown of “phytic acid.” Phytic acid is a natural compound in grains that binds to minerals like iron, zinc, and magnesium, preventing their absorption in the body. The long fermentation process neutralizes phytic acid, making these minerals more available to the body.

- Natural Preservation: The acidic environment created by the bacteria is a powerful natural preservative. This acidity inhibits the growth of mold and other undesirable microorganisms, extending the shelf life of the bread without the need for chemical preservatives.

Sourdough as a “Functional Food”

Many know sourdough bread only for its distinctive taste, but its true value extends beyond that. With growing consumer awareness about digestive health, sourdough bread is becoming a “functional food.” Its ability to improve mineral absorption and be more easily digested makes it an attractive option for health-conscious consumers. This means that as bakers, we can market our product not only based on its “authentic, rustic flavor” but also on its “tangible health benefits.” This strategy moves us into the growing market of health-oriented products and attracts customers who might never have been buyers of regular white bread. The technology of controlled starters is the tool that allows us to deliver this promise of health consistently and with stable quality.

My Experience: Our biggest challenge in mass-producing sourdough bread was maintaining the stability and activity of the starter. Fluctuations in the workshop’s temperature and humidity disrupted its performance. By investing in proofing rooms (proofers) with precise temperature and humidity control, we were able to create a stable environment for our starters. This investment allowed us to produce thousands of loaves of sourdough bread daily with a completely consistent flavor and texture.

The Revolution in Heat and Automation

3- Precision with Automated and Continuous Mixing Systems 🌀

The mixer is the beating heart of any bakery. For decades, we worked with the “batch” method: a large bowl of dough was prepared, emptied, and then the next bowl. But today, “continuous mixing” technology is completely changing this process. In this system, a constant stream of raw materials enters the mixer, and a continuous stream of finished dough exits.

Continuous Mixing Technology in Action:

- Batch vs. Continuous: In a batch system, each dough has an independent identity and may have slight differences from the previous or next batch. In a continuous system, the entire production is a single, uniform stream.

- Key Advantages:

- Absolute Uniformity: These systems eliminate inter-batch variables, producing a product with a completely consistent weight, size, and texture.

- Reduced Labor and Energy: The process is fully automated and, due to the absence of frequent stop-start cycles, consumes less energy.

- Superior Hygiene: Human contact with the dough is minimized, which means a higher level of hygiene.

- Precise Recipe Control: Modern systems use precise “Loss-in-Weight” feeders to inject raw materials, ensuring that the recipe is followed with perfect accuracy at all times.

This Technology is About Risk Reduction, Not Just Product Improvement

Perhaps the most significant and hidden benefit of a continuous mixing system is the dramatic reduction of “dough at risk.” Imagine in a batch system, you have a 2000 kg mixer. If a downstream machine (like a divider or rounder) malfunctions and the line stops, you are left with 2000 kg of finished dough that is rapidly over-fermenting and may be entirely lost. This is a huge financial and operational risk. But in a continuous system, the amount of dough between the mixer and the next machine at any given moment is much smaller (e.g., 1000 kg versus 5000 kg in a batch system with similar capacity). In the event of a line stoppage, the amount of waste will be far less. This perspective changes the investment equation from “increasing productivity” to “increasing operational resilience and reducing waste.”

My Experience: We started with 120 kg spiral mixers and gradually moved towards a continuous mixing line. The initial investment was heavy, but the reduction in dough waste and the unparalleled consistency of the final product resulted in a return on investment in less than two years.

4- The New Era of Baking with Wave Energy (Infrared & Microwave) 🔥

Traditional baking works by transferring heat from the outside in. But wave technologies disrupt this equation. They use different parts of the electromagnetic spectrum to bake bread faster, more efficiently, and with a different quality.

Wave Technologies in Action:

- Microwave: These waves generate heat volumetrically from the inside by vibrating the water molecules within the dough. This method cooks the crumb of the bread very quickly and sets its structure.

- Infrared: These waves radiate thermal energy directly onto the surface of the dough and are highly effective for creating crust color and texture.

- The Hybrid Advantage: The real magic happens when these two technologies are combined. Microwaves quickly cook the crumb and prevent excessive moisture loss, while infrared creates a golden, crispy crust. This synergy drastically reduces baking time (by 20% to 40%), lowers energy consumption, and produces a product with higher internal moisture.

This Technology Decouples Crumb and Crust Baking

In a conventional oven, the crumb and crust of the bread are baked by a single heat source from the outside. This is an inherent limitation. To achieve a dark, crisp crust, we often have to accept the risk of drying out the crumb. Hybrid technology eliminates this limitation. By combining microwave (for internal baking) and infrared (for surface baking), we can control the cooking of the crumb and the browning of the crust as two completely independent variables. We can achieve the ideal internal texture and temperature with microwaves and then create the exact crust color we want with infrared, without these two processes negatively affecting each other. This is a level of control that is impossible in traditional ovens.

My Experience: We have not yet fully implemented a hybrid IR/Microwave oven, as their initial cost is high. However, in the pilot tests we conducted for our snack bread production line, the 30% reduction in energy consumption and the exceptionally high moisture content of the final product have convinced us to invest in the future.

5- A Baker’s Guide to Tunnel and Hybrid Ovens ⚡️

If continuous mixers are the heart of the industrial bakery, tunnel ovens are its arteries. These machines are designed for mass, continuous, and uniform production of specific products and form the backbone of any modern bread factory.

Tunnel Oven Technology in Action:

- How It Works: A conveyor belt moves products through a long tunnel divided into several heating zones. This structure ensures that every loaf of bread experiences the exact same thermal profile.

- Direct vs. Indirect Heat: The best models, like the ovens produced by Mashhad Baking Industries, use an indirect heating system. In this system, the burner flame is located in a separate chamber (heat exchanger), and only hot, clean air is blown into the baking chamber. This design prevents toxic gases from combustion from coming into contact with the bread, resulting in better flavor, more uniform color, and longer product shelf life.

- Key Features: The ability to independently adjust the temperature in each zone, a programmable steam injection system, and conveyor speed control provide high flexibility for baking various types of bread.

Tunnel Ovens are Process Control Tools

The true power of a modern tunnel oven lies not just in its high production capacity, but in its ability to create a precise and repeatable “baking profile.” Instead of placing the bread in an environment with a constant temperature (like a deck oven), we send it on a planned journey.

- Zone 1: High heat and abundant steam for the initial oven spring.

- Zone 2: Medium, dry heat to set the crumb structure.

- Zone 3: Higher, radiant heat for final crust coloring.

This capability transforms baking from a static event into a dynamic, fully controlled process and is the key to achieving absolute uniformity on an industrial scale.

My Experience: For our lavash and barbari bread production lines, we chose a tunnel oven from Mashhad Baking Industries. Its indirect heating system was a deciding factor. We saw a noticeable increase in the shelf life of our breads, which we attribute directly to the cleaner baking environment of this oven. Operating 16 hours a day, this machine has shown incredible reliability.

6- Precise Steam Control in Advanced Ovens 💧

Steam is one of a baker’s most powerful yet delicate tools. It’s not just for moisturizing; it’s a key factor in the formation of bread volume and crust, and modern ovens give us unprecedented control over it.

The Science of Steam in Action:

- The Role of Steam: When steam is injected into the oven in the first few minutes of baking, it condenses on the cool surface of the dough, creating a thin film of water. This layer keeps the dough surface moist and elastic, allowing the bread to expand to its maximum volume (Oven Spring) without cracking. Furthermore, this moisture gelatinizes the starches on the crust surface, which, after drying, turns into a shiny, thin, and crispy crust.

- Steam Control Technology: Modern deck ovens, like the models produced by Mashhad Baking Industries, feature programmable steam injection systems. The baker can set the exact injection moment, duration, and volume of steam for each deck independently. This feature allows us to create custom baking profiles for different products (e.g., baguettes on one deck and ciabatta on another).

Steam is a Phase-Driven Tool

The effectiveness of steam is entirely dependent on its timing. Injecting it at the wrong time or for too long has the opposite effect. The baking process has two main phases:

- Expansion Phase: In the first few minutes, the bread rapidly gains volume. In this phase, the presence of steam is crucial to keep the crust soft and not hinder growth.

- Setting and Coloring Phase: After the oven spring is complete, the steam must be vented from the oven chamber to allow the bread surface to dry and form a crispy, golden crust. If too much steam remains in the oven, the crust will become thick and leathery.

Programmable systems are revolutionary because they allow the baker to automate this critical transition with flawless precision for every bake—a task that previously depended on the baker’s feel and experience.

My Experience: Mastering the steam system of our Mbico deck oven transformed the quality of our baguettes. We defined a program with a powerful steam injection for 30 seconds at the beginning of the bake and a complete vent after 10 minutes. The result was a 15% increase in volume and a perfectly shiny, cracked crust that was previously impossible to achieve consistently.

The Bakery of the Future

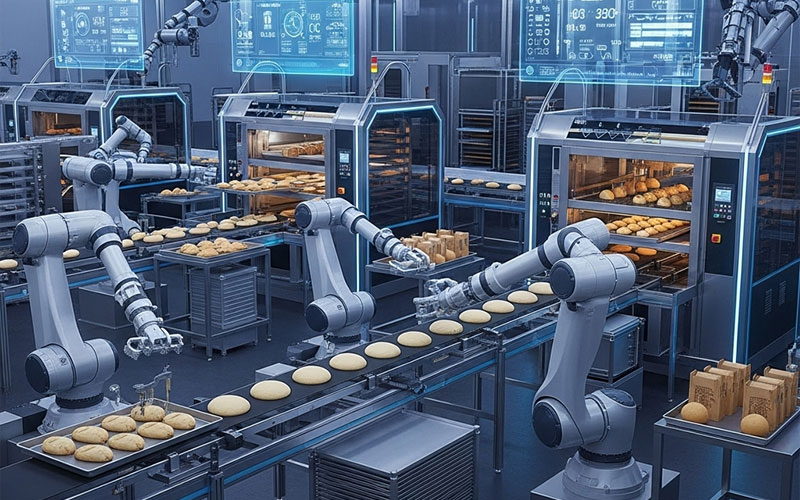

7- The New Workforce: Robotics and Automation in the Production Line 🤖

When people talk about automation, many think of replacing humans with machines. But I see it differently: using robots to perform repetitive, heavy, and high-precision tasks, so that our skilled bakers can focus on creative and specialized work.

Robotic Technology in Action:

- Applications:

- Pick and Place: Delta robots can pick up light products like cookies or small breads from a conveyor belt and place them into packaging at very high speeds.

- Packaging and Palletizing: Articulated robotic arms handle final packaging, placing items in cartons, and stacking cartons on pallets. This not only increases speed but also prevents physical injuries from lifting heavy loads.

- Dough Handling: Soft and intelligent robotic grippers can divide and move dough portions without damaging them.

- Decorating: Robots can perform cake and pastry decorating with cream or chocolate with unparalleled precision.

- Key Advantages: A dramatic increase in production speed and capacity, 24/7 operation capability, unrivaled product uniformity, and a significant improvement in hygiene by reducing human hand contact with the product.

Automation is a Response to the Labor Crisis

In recent years, the baking industry has faced a serious challenge of skilled and semi-skilled labor shortages and high employee turnover rates. From this perspective, investing in robotics is not just about reducing costs; it is a strategy to mitigate operational risk arising from labor market fluctuations. A robot doesn’t get sick, doesn’t request leave, and performs work with consistent quality. This allows us to move our valuable employees from tedious and strenuous jobs (like stacking cartons on a pallet) to higher value-added tasks (like quality control, new product development, or equipment performance monitoring). This shift increases job satisfaction and helps retain experienced staff, which is a hidden but very important return on investment.

My Experience: We started with a simple robotic arm for final packaging. The initial cost was recovered in 18 months through increased speed and the complete elimination of costs related to occupational injuries. But more importantly, we were able to train two of our line workers for the position of senior quality control technician, and that was a huge win for us.

8- The Challenge and Triumph of Functional Breads 🌿

The bread market is changing. Consumers are no longer just looking for bread to fill them up; they are looking for products that contribute to their health. This is where “functional” or health-oriented breads, such as whole-grain, fiber- and probiotic-enriched, and especially gluten-free breads, come into play.

Gluten-Free Bread Technology in Action:

- The Main Challenge: Gluten, the main protein in wheat, creates an elastic and cohesive structure that traps the gas from fermentation, giving bread a soft and voluminous texture. Removing gluten gives us a batter-like dough, which, when baked, results in a dense, firm, crumbly bread with a short shelf life.

- The Structuring Toolbox: To overcome this challenge, we use a combination of alternative ingredients:

- Alternative Flours: Gluten-free flours like rice, corn, quinoa, buckwheat, and legume flours form the base of the formulation.

- Hydrocolloids: These compounds (like xanthan gum, guar gum, or psyllium) increase the dough’s viscosity by absorbing water, simulating the function of gluten in creating structure and retaining moisture.

- Proteins and Enzymes: Adding other proteins (from sources like soy or legumes) and specific enzymes can help create a weak network to trap gas, improving the bread’s volume and texture.

Gluten-Free Production is a Supply Chain and Operational Challenge

Successfully producing gluten-free bread on an industrial scale is much more than finding a good recipe. It is a full-fledged operational commitment. A bakery cannot simply decide to produce gluten-free bread on the same production line as wheat bread. Even trace amounts of wheat flour (cross-contamination) can be dangerous for celiac patients. Therefore, success in this area requires a fundamental change:

- Certified Supply Chain: Collaborating with suppliers who can guarantee the purity and gluten-free status of their raw materials.

- Physical Separation: Having completely separate storage, mixers, ovens, and tools for gluten-free products.

- Strict Hygiene Protocols: Implementing rigorous control programs (like HACCP) to prevent any potential contamination.

The operational complexity and the high risk of damaging the brand’s reputation if these principles are not followed are the biggest barriers to entering this market and a continuous operational cost.

My Experience: Our gluten-free bread project took two years. The easier part was developing the formulation. The difficult part was redesigning a section of the factory and training staff to implement a flawless allergen control system so that we could confidently deliver a safe product to the consumer.

9- Smart Packaging for Increased Freshness and Trust

Packaging is no longer a simple wrapper. Modern packaging is an active guardian that extends product life and communicates with the customer. This field is divided into two main branches: active packaging and intelligent packaging.

Modern Packaging Technology in Action:

- Active Packaging: This type of packaging “interacts” with the environment inside the package to preserve product quality.

- Oxygen Absorbers: Small sachets or layers in the packaging film that absorb residual oxygen, preventing mold growth and oxidation.

- Antimicrobial Films: Packaging coated with natural antimicrobial extracts (like plant extracts) that inhibit bacterial growth.

- Moisture Regulators: Materials that absorb excess moisture, preventing the bread from becoming soggy or moldy.

- Intelligent Packaging: This type of packaging “communicates” information about the product’s status.

- Time-Temperature Indicators: Labels that change color if the product is exposed to improper temperatures for a prolonged period.

- Freshness Indicators: Sensors that react to gases produced by spoilage and alert the consumer with a color change that the product is no longer fresh.

Smart Packaging is a Trust-Building Tool

At first glance, it seems the main goal of these technologies is to extend the product’s shelf life. But there is a secondary, more powerful function: creating a direct and transparent relationship based on trust with the end consumer. A freshness indicator that tells a customer “Do not consume this bread” might seem detrimental to sales. But in reality, this message demonstrates a brand’s commitment to quality and consumer health, beyond immediate profit. This transparency builds incredible trust. When a customer sees that a brand is willing to be honest about its product’s spoilage, they will purchase products without this warning with greater confidence. Packaging transforms from a lifeless wrapper into an honest messenger for the brand.

My Experience: We are currently exploring the use of antimicrobial films for our organic bread line. Our goal is to increase the product’s shelf life in stores by 3 to 4 days, which could significantly reduce waste and returns from retailers and allow us to distribute to a wider geographical area.

10- The Final Frontier? Art and Personalization with 3D Bread Printing

3D printing in the baking industry is still in its early stages, but it shows us an exciting vision of the future: the production of completely customized products with complex and personalized designs that are impossible to make by hand.

3D Printing Technology in Action:

- How It Works: First, a 3D model is designed in software. Then, a printable food material (like dough, puree, or chocolate) is placed in the printer, and the machine deposits it layer by layer based on the digital model to create the final shape.

- Applications: Currently, this technology is mostly used for creating highly intricate decorations for cakes, luxury desserts, and sugar or chocolate structures. This technology allows for the creation of extraordinary geometric shapes.

- Limitations: The process is currently very slow, expensive, and limited to raw materials that have a smooth, injectable consistency. Therefore, it is not suitable for the mass production of regular bread.

Beyond Fancy Shapes: The Real Potential of 3D Printing is in “Mass Customization” and Smart Nutrition

Although 3D printing is mostly used today for creating creative shapes, its core technology—the “precise deposition of materials based on a digital file”—holds a much greater potential. Imagine instead of a shape design file, we feed the machine a “nutritional profile file.”

A customer could specify their nutritional needs (e.g., low-sodium, high-protein, enriched with vitamin D, free of a specific allergen). The machine could then produce a bread or snack by precisely injecting raw materials, exactly according to that specific individual’s needs. This is no longer just product manufacturing; it is providing “personalized health services.” This vision could completely transform the future of the food industry.

My Experience: This is an area we are currently observing from a distance. At present, this technology is mostly used in luxury pastry shops and research centers. But its potential for producing customized nutritional products is something we are closely monitoring for the next decade.

Conclusion: The Future is Baked into Our Craft—A Fusion of Tradition and Technology

Our journey from brick ovens to smart production lines shows that the modern baker is a multifaceted professional: part artist, part scientist, part engineer, and part business strategist. The technologies we have reviewed are not a threat to our art; they are powerful tools that, when used with skill and experience, allow us to produce better, healthier, higher-quality bread with a longer shelf life than ever before. From the science of enzymes to achieve a clean label, to automation to overcome labor challenges, and smart packaging to build trust, each of these innovations is a response to a real need in today’s market.

My final message to my colleagues is to cultivate a mindset of continuous learning. We must strategically invest in technologies that align with our business goals, just as we have confidently navigated this path by choosing reliable partners like Mashhad Baking Industries (Mbico). The future belongs to the bakers who can blend the best of tradition with the smartest of technology.

Explore MBICO's categories

Bakery equipment

13 Products

bulk and semi-bulk bread baking ovens

3 Products

Bulk Breads Baking equipment

14 Products

Confectionery equipment

7 Products

Mini ovens

3 Products

Pizza and food ovens

4 Products

Baking equipment

25 Products

Bakery oven

5 Products

Tafton baking ovens

3 Products

Barbari baking ovens

4 Products

Sangak bakery ovens

3 Products

Lavash baking ovens

3 Products

Pastry and confectionery ovens

3 Products

Baking ovens

10 Products

Mobile baking machines

4 Products

Explore MBICO's products

Pastry Dough Sheeter

Dough pouring machine

Rimok Bakery

Bakery & Pastry Trolley

Dough Kneading Table

Kitchen trailer

2-Roll Dough Sheeter (2-Roll Tabletop Dough Sheeter)

Dough Bowl