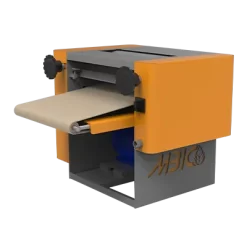

steam Generator for Bread Production: A Comprehensive Guide

A steam generator is a crucial piece of equipment in the production of bulk and semi-bulk breads. It is used to provide humidity and heat to the proofing room, facilitating the final fermentation of the dough. The steam generator boasts a unique design capable of producing a large volume of steam in a short period.

Generates Steam & Humidity for Fermentation Chamber and Generates Steam & Humidity for Fermentation Chamber. Steam Generator provides steam, humidity and heat for fermentation chambers with the minimum energy consumption. Both humidity and temperature are adequately controllable and adjustable; so homogenic heat and steam distribution results to high quality products.

Functionality and Features:

Also known as a steam unit or steam generator unit, this device features a temperature and humidity control system. This allows the operator to make the necessary fermentation adjustments based on the type of bread being produced.

The control system, housed in an electrically insulated panel, is provided separately and can be installed outside the proofing room or on the external body of the proofer. The control system offers functionalities such as turning the device on and off, adjusting temperature and humidity, and displaying the temperature and humidity levels inside the proofer.

Due to its use in humid environments, the body is made of stainless steel to resist moisture and prevent rust. This feature is crucial for locations constantly exposed to humidity. The use of stainless steel in the body construction increases the device’s lifespan and reduces the need for frequent maintenance and repairs.

Key Features of the Steam Generator:

- Adjustable heat

- Adjustable humidity

- All-stainless steel body

- Minimal space occupancy

- Humidity and temperature display

- Steam production tailored to space dimensions

- Easy-to-use control panel for operators

- Easy transport and installation in various spaces

- Reduced water and electricity consumption compared to traditional models

Advantages:

- Direct and significant impact on improving bread quality and consequently reducing waste

- Compliant with Iranian national standards

- ISO 9001 certified

- Warranty and after-sales service

Maintenance and Upkeep:

Regular maintenance is essential for optimal performance. Consult the user manual for specific maintenance procedures.

Installation:

For optimal performance, the steam generator should be placed on a flat and level surface. This helps prevent the device from slipping and ensures its stability over time. Before installation, it is recommended to carefully check and level the ground surface to ensure better performance and efficiency of the steam generator.

Demonstration Video:

A video demonstrating the operation of the device is available.

Warranty and After-Sales Service:

The product comes with a warranty and after-sales service.

Pricing:

To receive a price quote for the steam generator, information on direct purchase from the factory, and pre-purchase consultation, please contact our sales experts through the following contact methods:

Phone Calls (Contact Numbers)

Factory:

+985132464090

Office:

+985138583180

Get in Touch

To receive consultation and connect with our sales experts, please submit your request through the Email below.

mbi@mbico.com

Frequently Asked Questions (FAQ):

-

What are some common names for the steam generator?

Steam generator unit, steam maker, fancy steam generator, steam generator device, fancy steam maker.

-

What is the body of the steam generator made of?

Stainless steel.

-

What is the use or application of the steam generator?

The steam generator is used to produce steam and provide heat in proofing rooms, especially in the bulk and semi-bulk bread industries.

-

What are the electrical requirements for the steam generator?

The steam maker can be produced with single-phase or three-phase power, depending on the customer’s needs and facilities.

Reviews

There are no reviews yet.