FIXED

Rotary Oven

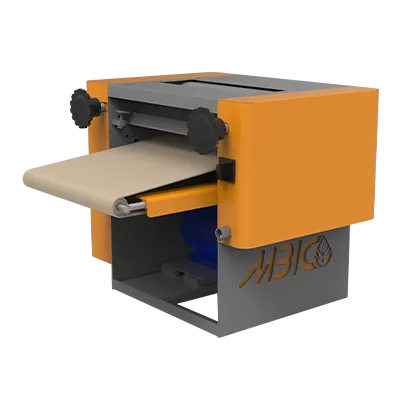

Fixed Rotary Semi-Automatic Oven for Baking Traditional Breads

Fixed Rotary Semi-Automatic Oven for Baking Traditional Breads

The fixed rotary oven from Mashhad Baking Industries, utilizing an indirect flame heating system and brick insulation, is considered one of the older, yet affordable, bakery machines. It enables bakers to produce various traditional Iranian breads such as Taftoon, Azerbaijani Lavash, Tehran Lavash, Barbari, and non-Iranian traditional breads, as well as various types of pizza, with high quality and performance. As the largest manufacturer of traditional bakery machines in the country, Mashhad Baking Industries, relying on its experience and expertise, has been able to meet the needs of bakers in the best possible way.

Introduction to the Fixed Rotary Baking Oven

The fixed rotary baking oven is one of the oldest products of Mashhad Baking Industries and has the capability to produce various types of traditional Iranian breads, including: Taftoon bread, Azerbaijani Lavash, Tehran Lavash, machine-made Lavash (floor-baked), Barbari bread, Khoshke (crispbread), Shirmal, Qandi bread, Kaak, dry bread, and various types of pizza with high quality and performance.

The fixed rotary baking oven, as a new innovation after clay ovens, became available to bakers and played a very important role in improving baking efficiency and quality. Due to its unique features, it quickly replaced clay ovens. This fixed bakery machine is the most suitable baking machine in terms of price.

Insulation of the Fixed Rotary Baking Oven

The insulation of the fixed rotary oven is done on-site by bricklaying. After the fixed rotary oven is installed at the desired location, the insulation process begins with bricklaying. This process is carried out by a bricklayer and uses materials such as gray brick, straw mud, salt, clay, and fiberglass to provide a solid and stable base for the machine and prevent excessive heat from entering the environment. The main purpose of this insulation is to prevent energy waste and prevent excessive heat transfer to the surrounding environment. In this way, the machine is able to operate optimally in various environmental conditions.

Fixed Rotary Baking Oven with Automatic and Semi-Automatic Baking Options

Automatic Baking (Without Baker)

In this mode, a dough sheeter is placed next to the fixed rotary baking oven as a replacement for manpower. The sheeter automatically performs the dough spreading operation without manual intervention. Using a sheeter in automatic baking increases productivity and reduces labor costs. In addition, it makes the production process faster and more efficient, as this machine is able to spread the dough evenly and continuously without needing to rest.

Semi-Automatic or Manual Baking

In this mode, manpower is present as a baker next to the fixed rotary oven and performs the spreading and transferring of the dough to the baking bed.

Advantages of the Fixed Rotary Baking Oven

- Multi-purpose baking machine and production of various breads

- Reduced bread waste

- Easy transportation in disassembled form

- Low depreciation of the baking machine

- Reduced fuel consumption compared to traditional ovens

Features of the Fixed Rotary Baking Oven

- Variety in cast iron size and dimensions

- Affordable price

- Complies with Iranian National Standards

- Use of food-grade stainless steel in the machine's exterior construction

- Adjustable temperature and baking time

In the fixed rotary machine, all control operations are performed through an electronic panel installed in the electrical panel. Using the control keys, the operator can easily make the necessary settings, including motor speed, temperature, and automatic shutdown time of the machine. The electricity required for the fixed rotary bakery oven is single-phase.

The fixed rotary baking oven uses a direct flame or indirect flame heating system for baking bread. The direct flame heating system is one of the methods used in the bakery industry to generate the heat needed for baking bread. In this method, the fuel reaches the heat source directly, and as a result, the heat is directly focused on the product, and the required temperature for baking the product is quickly achieved, and the baking time is reduced. However, there will be pollution from the fuel in the baking bed. The fixed rotary machine has two heat exchangers, and the fuel required for the burner, depending on the customer's needs and the common fuel in the region, can be gas, diesel, or oil.

Installation and Setup of the Fixed Rotary Oven

In coordination with the after-sales service unit of Mashhad Baking Industries, the fixed rotary bakery oven is installed and set up free of charge by experienced technicians of the company. After delivery and installation of the fixed rotary oven at the operation site, with the guidance of the after-sales service unit by a builder, the insulation of the fixed bakery machine is done by bricklaying. In the next step, the technician will train you on the machine setup steps, initial settings, proper use of the machine, maintenance, and after-sales service to ensure optimal performance of the rotary machine and its greater efficiency over time.

Warranty and After-Sales Service of the Fixed Rotary Oven

The fixed rotary bakery oven with a 12-month warranty and lifetime after-sales service assures customers of the product's quality and performance and demonstrates Mashhad Baking Industries' commitment to resolving any problems or breakdowns during the warranty period. In case of any problem, customers can contact the after-sales service unit and benefit from repair and replacement services of consumables.

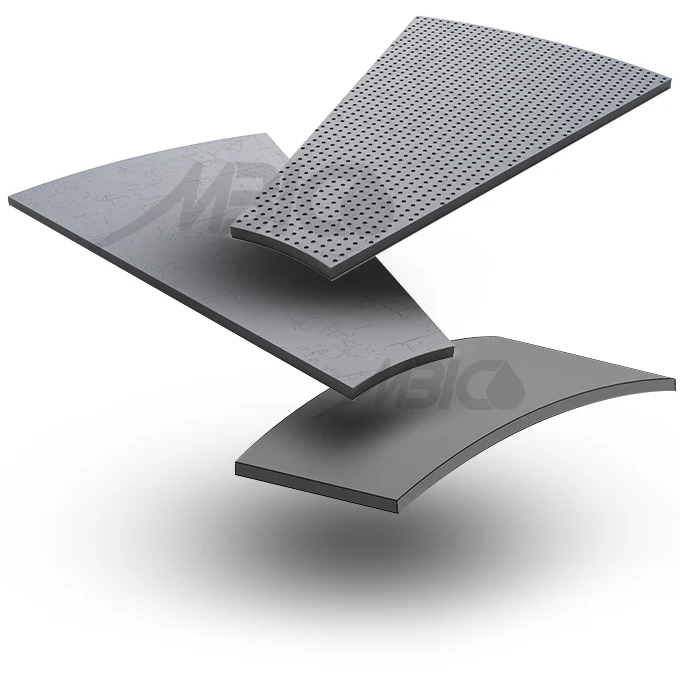

Sizing and Variety of Cast Iron in the Fixed Rotary Baking Machine

In the baking machine, the dough is placed in a cast iron bed to be transformed into bread. Each type of bread has a specific shape that requires a different bed for baking. Therefore, the fixed rotary machine is produced in different types of cast iron to meet this need.

Smooth Cast Iron: For baking traditional Iranian breads such as Taftoon and Barbari, which have a smooth and uniform surface, the fixed rotary machine with a smooth cast iron model is suitable.

Perforated Cast Iron: For baking Azerbaijani Lavash, which has small and regular holes on its surface, the fixed rotary machine with a perforated cast iron model is suitable. This cast iron, by creating homogeneous and precise holes on the surface of the bread, bakes it evenly and gives the Azerbaijani Lavash a beautiful and attractive appearance.

Curved Cast Iron: For baking traditional breads such as Iraqi Samoon, the fixed rotary machine with a curved cast iron model is recommended as a suitable option. This shape of cast iron makes it possible to provide more curve for the bread, which helps you to easily spread the dough wider and prepare a bread with a beautiful appearance similar to traditional examples.

Models and Technical Specifications of the Fixed Rotary Baking Machine

The production of the fixed rotary machine according to the type of bread and customer needs at Mashhad Baking Industries is a wide and multifaceted process. Fixed rotary machines are produced with different dimensions and capacities and with various surfaces to best match the different needs and specifications of breads. This flexibility in dimensions and production capacity allows bakers to choose a machine that exactly matches their needs and improves the efficiency and productivity of their bakery. This machine is manufactured in 4 types and 32 models at Mashhad Baking Industries.

Production of Fixed Rotary Machine in Two Different Facades

The fixed rotary bakery machine is the first and oldest bread baking machine at Mashhad Baking Industries. Currently, this baking machine can be produced and offered to customers with a new and different appearance compared to the previous model. By maintaining all the technical features and high quality of this product, with the aim of improving user experience and adapting to modern design styles, we provide this product to you.

Frequently Asked Questions about the Fixed Rotary Baking Oven

The fixed rotary baking oven has either a direct flame or indirect flame heating system.

All traditional Iranian breads such as Lavash, Barbari, and Taftoon, as well as pizza.

The semi-automatic fixed rotary oven is produced in various sizes according to the required production capacity, with the following technical specifications:

- MBI D 200

- MBI D 250

- MBI D 300

- MBI D 350

This translates to the following approximate sizes:

- 2-meter rotary baking oven

- 2.5-meter rotary baking oven

- 3-meter rotary baking oven

- 3.5-meter rotary baking oven

Depending on the type of bread to be produced, different types of cast iron are used, such as smooth cast iron, perforated cast iron, and curved cast iron, manufactured by Mashhad Baking Industries.

For baking Barbari bread with a fixed rotary oven, the 3-meter fixed rotary baking oven is recommended.

For baking Lavash bread with a fixed rotary oven, the 2-meter fixed rotary baking oven is recommended.

This timeframe can vary depending on the number of orders in the production queue. You can contact our experts for more information.

- Affordable price

- Reduced bread waste

- Ability to produce various types of bread

- Low depreciation of the baking machine

- Multi-purpose baking machine

- Easy transportation in disassembled form

- Reduced fuel consumption compared to traditional ovens

One-year warranty and lifetime after-sales service.

- Fixed rotary baking oven

- Brick-lined bakery oven

- Direct flame oven

- Masonry bakery oven

- Affordable bakery oven

- 2-meter fixed rotary bakery oven

- 2.5-meter fixed rotary bakery oven

- 3-meter fixed rotary bakery oven

- 3.5-meter fixed rotary bakery oven

The fixed rotary baking oven is insulated on-site by bricklaying, which is why it is known as the "fixed rotary oven" or "brick-lined bakery oven." In this process, after the bakery oven is installed at the desired location, insulation is carried out by a builder using materials such as gray brick, straw mud, salt, clay, and fiberglass.

Price of the Fixed Rotary Baking Oven

Due to the variety of models of the fixed rotary baking oven and the importance of choosing the best fixed rotary baking oven based on your needs, you can contact our sales experts through the communication channels for accurate consultation and information about the price of the fixed bakery oven. Our sales team is ready to provide information and guidance to help you choose the most suitable model of the fixed rotary baking oven and receive complete information about price and technical specifications.

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com