The Confectionery Rack Oven for Baking Pastry from Mashhad Baking Industries, utilizing an indirect heating system and hot air circulation, is capable of baking a variety of pastries, cakes, cookies, large and semi-large breads, as well as frying chicken and fish with perfectly even and uniform heat. Mashhad Baking Industries is the largest manufacturer and seller of pastry and bread ovens in the world.

The Confectionery Rack Oven for Baking Pastry is an exceptional and versatile choice within the industrial oven category. This oven is capable of baking a variety of pastries, cakes, cookies, large and semi-large breads, as well as frying chicken and fish with excellent quality. It is ideal for various establishments such as bakeries, fancy cake shops, catering services, and industrial kitchens. As a multifunctional tool, it enhances production quality and increases customer satisfaction. The rotary pastry oven is also commonly referred to as a bread rotary oven.

The rotary pastry oven utilizes a rotating system and hot air circulation for baking products. Using the rotation system, the carriage moves in a specific direction inside the oven, ensuring that the products are baked evenly and more effectively. The items inside the baking chamber are cooked by the hot air, which is circulated by a centrifugal fan, allowing for thorough baking of the products without drying or burning the surface.

The heat exchanger used in the rotary pastry oven is of the Winkler Germany design, which not only ensures very high efficiency but also uses less fuel. The industrial pastry oven from Mashhad Baking Industries offers excellent performance, quality, and reliability, enabling it to meet the challenges of modern food services while enhancing the craftsmanship of old-world baking. With the help of Mashhad Baking Industries' rotary pastry oven, cakes, pastries, and breads are baked to perfection, providing customers with a delightful and enjoyable experience with these exceptional products. This efficient and versatile machine is an excellent choice for bakeries, restaurants, and catering businesses, adding significant value to your production.

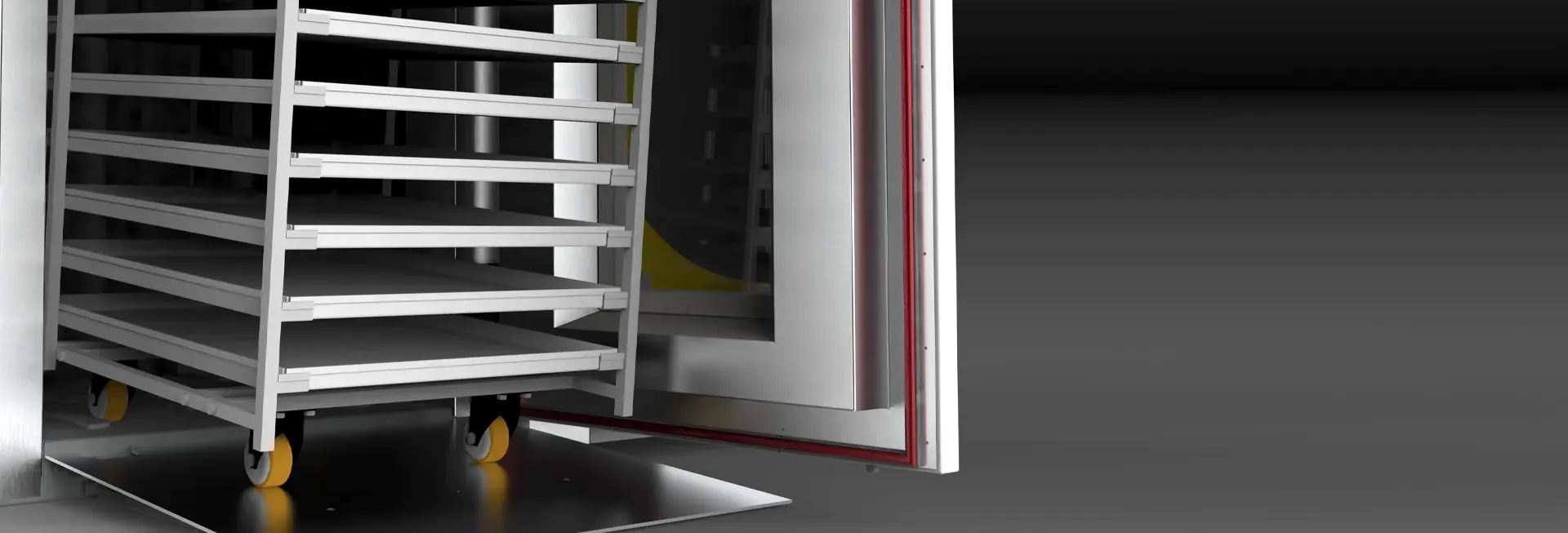

The carriage and baking tray in the rotary pastry oven

The industrial rotary pastry oven features a carriage and 16 baking trays. The oven allows for the use of trays with different dimensions, providing greater versatility and flexibility in baking various products. This capability enables users to bake a wide range of products in different sizes. By default, each rotary pastry oven comes with a 16-tray carriage, with trays measuring 60x80 cm, but it can also accommodate trays of sizes 60x40 cm and 60x90 cm. When using 60x40 cm trays, two trays will fit on each level of the carriage, which is why the rotary pastry oven is also known as the "32-tray oven" among users. This allows bakers and users to easily bake dough of various sizes and prepare a diverse array of products in the oven.

Steam system in rotary pastry ovens

After preparing the dough and placing it on the trays, the trays are positioned on the oven's carriage. Once the dough has rested, the carriages are moved into the rotary pastry oven chamber to begin the baking process. This efficient and versatile machine is produced in two models: one with a steam system and one without, making it an excellent choice for bakeries, restaurants, and catering services, and adding significant value to your production.

Rotary Pastry Oven without Steam System

The rotary pastry oven without a steam system, also known as the bakery and pastry oven, is suitable for baking products that require less moisture, such as cookies, pastries, and certain foods. By not using a steam system, this oven allows for more precise temperature control, resulting in more even and better baking of pastry products.

Rotary Pastry Oven with Steam System

The rotary pastry oven equipped with a steam system is ideal for baking products that require steam, such as various types of large and semi-large breads. Due to the high dough volume, these products need a moist environment to bake evenly with a golden color and the right level of moisture, ensuring high quality and excellent texture. This oven, commonly known as the "Fancy Bread Rotary Oven," uses the steam system to create uniform humidity inside the oven, leading to excellent and satisfying results in baking products.

The control operations of the electronic systems in the rotary pastry oven are managed by the PLC installed on the control panel and can be displayed and adjusted via the HMI monitor. The operator can use the touch keyboard to set various parameters, including the minimum and maximum temperature, steam, device on/off times, baking timer, and pre-programmed settings. Additionally, the operator can monitor the internal chamber temperature, the status of the fan and burner, and other relevant functions.

HEEATING

SYSTEM

The heating system in the rotary pastry oven is entirely indirect, and the products inside the baking chamber are cooked by hot air circulation, which is facilitated by a centrifugal fan. This method helps maintain the natural flavor and moisture of the products and plays a crucial role in achieving desirable and satisfying results. The rotary pastry oven requires only one burner to generate heat and operates on fuel. The type of fuel required for the burner can be either gas or diesel, depending on the customer's preference and the common fuel available in the region. Additionally, the rotary pastry oven is also available in a fully electric version, where electrical power is used to meet its heating requirements.

Advantages of Rotary Pastry Ovens

- Uniform baking and thorough cooking of products

- Exceptional steam output capacity

- Ability to observe products during baking

- Baking with a 100% indirect heat system

- Lower energy consumption due to superior insulation

- Compliant with the latest global standards

- Full stainless steel exterior

- Cabin material available in two options: full stainless steel or stainless steel-coated steel

Features of Confectionery Rack Oven for Baking Pastry

- Equipped with a unique rotary system with gentle rotation

- Automatic fan stop

- Halogen lamp for lighting

- Safety door lever

- Complete silicone door seal

- Double-glazed full-view door window

- Ramp or elevator for easy entry and exit of the carriage

- Very simple air adjustment system

Packaging and shipping of rotary ovens for bakery and pastry

For the transportation and relocation of rotary ovens for bakery, a ceiling crane or forklift can be used. The oven must be moved vertically, which is why special hooks are installed on the top of the device to connect it to the crane. Using a chain, the oven is connected to the crane and easily loaded and moved. Additionally, it is possible to move the device with a forklift. In this case, the forklift lifts the oven from the side using its long forks and transports it to the desired location. With careful handling and caution during this process, it is ensured that the device arrives safely at its destination, and customers receive their equipment in optimal condition.

Installation and Setup of Pastry Oven

The rotary pastry oven is installed and commissioned free of charge by the experienced technicians of Sanaye Pakhte Mashhad company, in coordination with the after-sales service department. After installation, the technician will perform an initial bake to check and verify the machine's performance quality. Additionally, the necessary training will be provided on initial settings, proper usage, maintenance methods, and after-sales service guidelines so that you can independently and efficiently operate the oven, achieving the best results in baking your products. Along with the delivery of the rotary pastry oven, a user manual, including maintenance and repair instructions, will be sent to customers.

Warranty and After-Sales Services for Pastry Ovens

The rotary pastry and confectionery oven from Sanaye Pakhte Mashhad company, equipped with the latest technology and high-quality materials, is presented to you as one of the best and most efficient industrial bakery ovens. This product comes with a one-year warranty to ensure complete satisfaction and peace of mind for our valued customers. The one-year warranty includes full support and troubleshooting from the date of purchase. In addition, lifetime after-sales service will always be available to you. By choosing our rotary pastry oven, you will have the best baking experience for various pastries, cakes, bread, and foods, and you can confidently rely on the excellent quality and performance of your product, making the most of your baking equipment.

Places and Professions Where the Rotary Pastry Oven and Fancy Oven Are Used

Catering Services and Restaurants

The steam rotary oven is an excellent choice for catering services and industrial kitchens. With its uniform air circulation, this oven ensures the thorough and even baking of a variety of foods, including pizzas, cakes, and pastries. Its high capacity and optimized performance reduce cooking time and enhance the quality of the dishes, making it an ideal choice for businesses involved in food preparation and distribution.

Owners of Pastry and Confectionery Businesses

The steam rotary oven with multifunctional capabilities is an ideal choice for owners of pastry and confectionery businesses. This oven, with its advanced steam injection system, allows for the baking of a wide range of large and semi-large breads such as artisan breads, as well as various pastries. It helps those who seek a combination of both pastry-making and confectionery, enabling them to meet different needs with a single device.

Adhering to the latest standards and using high-quality, durable raw materials play a crucial role in the long lifespan and optimal performance of the rotary bakery oven. By following up-to-date standards, the rotary bakery oven is designed and built to be reliable and safe, which enhances user confidence in the product.

Iran National Standard Certification

ISO 9001 Certification

GOST Certification – Russia

CE Certificate Europe

CSA Certificate Canada

UL Certificate Canada

Models and Technical Specifications of Confectionery Rotary Ovens

If customers have size limitations for the entrance door of the location where the rotary oven will be installed, the oven will not be fully assembled at the factory and will be delivered as separate components. After the components are transported to the final location, the company's technicians will proceed with the final assembly of the rotary oven. This assembly phase includes connecting and securing the parts, tightening screws and bolts, installing various components, and ensuring the necessary connections for optimal oven performance. This assembly method provides flexibility to accommodate different space sizes and limitations, enabling easy and efficient installation in various locations.

MBI DR 2100 I

dimensions: 244*198*240

Cabin material: ST37 steel

Steam condition: Steam-free

Electrical voltage: 220-380 volts

Fuel type: gas / diesel / electric

Engine power (kilowatt): 2.2

Fuel consumption: 50M-45L

Baking capacity in 8 hours: 800kg

MBI DR 2100 IS

dimensions: 244*198*240

Cabin material: ST37 steel

Steam condition: Steam-equipped

Electrical voltage: 220-380 volts

Fuel type: gas / diesel / electric

Engine power (kilowatt): 2.2

Fuel consumption: 50M-45L

Baking capacity in 8 hours: 800kg

MBI DR 2100 S

dimensions: 244*198*240

Cabin material: Stainless steel

Steam condition: Steam-free

Electrical voltage: 220-380 volts

Fuel type: gas / diesel / electric

Engine power (kilowatt): 2.2

Fuel consumption: 50M-45L

Baking capacity in 8 hours: 800kg

MBI DR 2100 SS

dimensions: 244*198*240

Cabin material: Stainless steel

Steam condition: Steam-equipped

Electrical voltage: 220-380 volts

Fuel type: gas / diesel / electric

Engine power (kilowatt): 2.2

Fuel consumption: 50M-45L

Baking capacity in 8 hours: 800kg