Deck Oven (Baking Bulk & Semi-Bulk Breads)

The deck oven from Mashhad Baking Industries, with its indirect heating system and abundant steam, is known as the best steam oven, capable of baking various bulk and semi-bulk breads, baguette bread, bulk Barbari bread, steamed bread, Sistani bread, sandwich bread, toast bread, various cakes and cookies, and some types of pastries. As the largest manufacturer and seller of steam ovens in Iran, Mashhad Baking Industries offers high-quality products that meet the professional needs of the bread and pastry industry.

Introduction to the Bulk and Semi-Bulk Deck Oven

The deck oven, or bulk and semi-bulk bread baking oven, is one of the most widely used and popular ovens in the field of baking, confectionery, and especially for baking bulk and semi-bulk breads, also known as fancy baking. The deck oven, with 100% indirect heat, enables baking various bulk and semi-bulk breads, baguette bread, bulk Barbari bread, steamed bread, Sistani bread, sandwich bread, hamburger buns, toast bread, various cakes and cookies, and some pastries. The fancy oven, with its indirect heating system, uses advanced technology that effectively distributes heat evenly throughout the baking area, resulting in even and excellent baking of products.

Due to the variety of applications of the deck oven, it is known by different names among its users, including: fancy oven, steam oven, 1600 deck oven, bulk and semi-bulk bread machine, 16-tray deck oven, 16-pan oven, and gas bulk and semi-bulk bread deck oven. Each of these names represents the capabilities and features of this product and is chosen depending on the needs of the users.

Steam in the deck oven ensures even heat distribution and prevents burning or incomplete baking of products, so bulk and fancy breads are baked evenly and with high quality. In addition, steam during baking helps maintain the moisture and freshness of the product's texture, resulting in a soft and delicious texture. This feature plays a significant role in improving the texture and final quality of the products and brings an enjoyable experience for consumers.

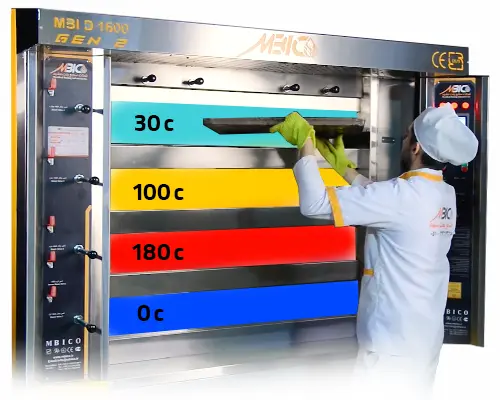

Advanced Temperature and Steam Control System of the Deck Oven

Steam and Temperature Setting for each unit

The presence of steam is very important for baking bulk and fancy products, as it has a direct impact on the baking quality and appearance of these products. In the deck oven, temperature and steam are controlled separately for each deck, which is one of the outstanding features of this oven and allows the user to have complete control over the temperature, steam, and baking time of each deck, thus producing diverse, uniform, and high-quality products in each work shift.

The steam generation power in the deck oven is very ideal and desirable, so that in addition to supplying the steam needed for the decks, it also supplies the steam needed for a separate fancy unit steam room through piping. Deck ovens are known as one of the best options for producing fancy breads due to their steam feature.

Uniform and Completely Soft Baking, Attractive Golden Appearance

Steam in the deck oven ensures even heat distribution and prevents burning or incomplete baking of products, so bulk and fancy breads are baked evenly and with high quality. In addition, steam during baking helps maintain the moisture and freshness of the product's texture, resulting in a soft and delicious texture. This feature plays a significant role in improving the texture and final quality of the products and brings an enjoyable experience for consumers.

Also, the presence of steam during baking increases the humidity inside the oven and forms a layer of steam on the surface of the products. This process not only produces soft and tender products with a golden color and excellent texture but also improves the quality and appearance of the products as a source of gentle and effective heat. The result is an enhanced purchasing and consumption experience for customers.

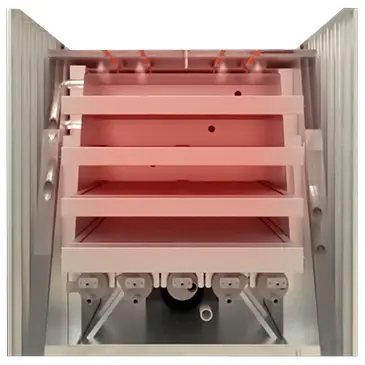

Heating System of the Fancy Deck Oven

The fancy deck oven uses an indirect heating system for baking products. This system, using a centrifugal fan, distributes hot air completely evenly inside the baking decks and bakes the products indirectly through hot air blowing. In this way, the final product is baked completely evenly from top to bottom in a completely hygienic environment.

The fancy deck oven only needs one burner to generate heat. The fuel required for the burner, depending on the customer's needs and the common fuel in the region, can be gas, diesel, or oil.

Control System of the Fancy Deck Oven

In the deck oven, all control operations are performed through an electronic panel installed in the electrical panel. Using the control keys, the operator can easily adjust settings such as temperature, baking time, baking programs, and automatic shutdown time of the machine. It is also possible to select predefined programs for baking various breads.

This advanced control system provides the ability to display temperature change curves, store information, and transfer it via USB. In addition, the device can be connected to computer systems and can be controlled and adjusted remotely. These advanced features are available upon customer request and increase efficiency and accuracy in the baking process.

Advantages of the Fancy Bread Machine

- Even baking of products

- Production of products with excellent texture and golden color

- Maintaining the freshness and taste of products

- Reduced fuel consumption

- Maintaining moisture in the baked product

- Very high variety of produced products

- Has up-to-date world standards

- Easy loading and unloading of the oven

- High production capacity

Features of the Fancy Bread Machine

- Automatic shutdown

- All-steel facade

- Has a strong steam system

- Use of three types of thermal insulation

- Equipped with safety valves

- Adjusting the amount of heat of the decks

- Adjusting the baking time and timer key

- Adjusting the steam operation time of the decks

- Even distribution of steam in each deck

Special Offers

Deck ovens have the ability to bake products on a stone floor or bake in trays and also be loaded and unloaded automatically. Using this feature, precise planning can be done for baking products and time and energy can be saved as much as possible. Implementing this feature requires the necessary equipment and mechanical and electronic systems.

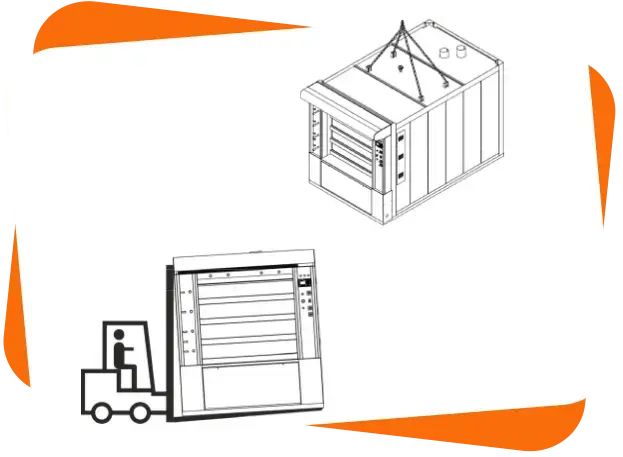

Packaging and Shipping of the Deck Oven

After manufacturing the bulk and semi-bulk bread baking oven, this machine is carefully inspected by the quality control unit to ensure that all necessary standards are met and the product is delivered to our valued customers without any defects.

Delivery is ex-factory, but for the convenience of our valued customers, Mashhad Baking Industries has collaborated with reputable transportation companies to ensure that loading and shipping of products are done in the best possible way for customers. Customers can have a confident purchase experience and benefit from our high-quality products by trusting the quality of our products and the ease of receiving them.

The deck oven must be transported vertically; for this purpose, special hooks are provided on the roof of the machine for connection to a crane, which allows loading and moving the machine using a chain. It is also possible to move the fancy oven with a forklift from the side of the machine using long forks.

Installation and Setup of the Fancy Deck Oven

The fancy deck oven, in coordination with the after-sales service unit of Mashhad Baking Industries, is installed and set up free of charge by experienced technicians of the company. In this process, you will be trained on how to use the device correctly, initial settings, and maintenance so that you can independently use all the capabilities of the deck oven and achieve the best results in baking bread and bulk and semi-bulk products.

Warranty and After-Sales Service of the Fancy Deck Oven

The fancy deck oven has a 12-month warranty and lifetime after-sales service. This warranty means the manufacturer's commitment to the quality and performance of the device, and in case of any breakdown or problem, customers can benefit from free repair and replacement services of consumables. Also, full support is available to ensure optimal use and maintain the device's performance.

Places and Businesses Using the Fancy Deck Oven

Due to the increasing popularity of bulk breads, starting a business in the field of baking and distributing bulk and semi-bulk breads, using suitable equipment and using modern marketing methods, can be considered a profitable and significant economic opportunity.

Bakeries and Industrial Bread Complexes

Using a deck oven with an indirect heating system allows bakeries to professionally produce traditional Barbari bread in a steamed form with high quality and improve the marketing and attractiveness of their products by creating variety in baking steamed breads and producing golden and uniform breads. Using the steam system, steamed breads, including Barbari bread, can be baked with excellent quality in a golden and uniform way.

Owners of Fancy and Confectionery Businesses, Cake and Cookie Factories

The fancy deck oven, due to its ability to produce and control steam, temperature, and baking time, is one of the best choices for owners of fancy and confectionery businesses, workshops, and cake and cookie factories. The deck oven enables baking diverse and high-quality products and allows the owners of these businesses to bake bulk and semi-bulk breads and various cakes and cookies in different and attractive shapes.

Standards and Certificates of the Fancy Deck Oven

Complying with up-to-date world standards in the design and manufacture of fancy and confectionery deck ovens, as well as using high-quality and resistant raw materials, ensures that this baking machine has a long life and maintains its optimal performance over time, and ultimately creates user trust and provides high-quality products. Standards, certificates, and technical regulations in the fancy and confectionery deck oven are determined to ensure its quality, safety, and optimal performance.

Iranian National Standard

ISO 9001 Certificate

GOST Russia Certificate

CE Europe Certificate

CSA Canada Certificate

UL Canada Certificate

Models and Technical Specifications of the Fancy Deck Oven

The fancy and confectionery deck oven is one of the most important and high-efficiency products for baking all bulk and semi-bulk breads and pastries, which has been produced by the experts of Mashhad Baking Industries for more than 20 years. This steam oven is designed and produced in a 4-deck configuration, each deck with a capacity of 4 trays (size 6080 cm or 6090 cm), with a separate steam system for each deck and with a very beautiful and efficient appearance. This oven is known and produced in Mashhad Baking Industries under the trade name "Baking Oven 1600."

Model

Dimensions (cm)

Voltage (V)

Deck Floor Material

Fuel Type

Fuel Type

Fuel Consumption (per ton)

Baking Capacity in 8 Hours (kg)

MBI DD 1600

Dimensions (cm): 209*325*185

Voltage (V): 220-380

Mesh - Stone

Power: 2.2kw

Gas/Diesel

Fuel Consumption (per ton): 66M-55L

Baking Capacity in 8 Hours (kg): 800-1000Kg

Frequently Asked Questions about the Fancy Deck Oven

The deck oven is produced in two models in terms of deck floor material: stone floor and mesh floor, in four decks, each deck having four 6080 or 6090 cm trays, totaling 16 trays, under the name "Oven 1600" at Mashhad Baking Industries.

The deck oven can bake a wide variety of bulk and semi-bulk breads, including baguettes, sandwich loaves, large Barbari bread, steamed breads, toast bread, as well as cakes, cookies, and some pastries.

The fancy bulk oven uses an indirect heating system for even and consistent baking.

The oven operates on either gas or diesel fuel. It can be configured for single-phase 220V or three-phase 380V electricity, and custom voltages (like 110V single-phase or 220V three-phase) can be provided for international customers.

The steam deck oven has an independent steam system for each deck, allowing for precise control of humidity during the baking process.

The fancy bulk bread oven is also known as: fancy oven, steam oven, bulk and semi-bulk bread machine, 16-tray deck oven, 16-pan oven, and 1600 deck oven.

The fancy oven can be produced as single-phase 220 volts or three-phase 380 volts according to customer order, or 110 volt single-phase or 220 volt three-phase for citizens of other countries as desired.

The fancy deck oven is installed and set up free of charge by experienced technicians from Mashhad Baking Industries, in coordination with the after-sales service unit. Training on proper use, initial settings, and maintenance is provided.

The bulk deck oven is suitable for bakeries, industrial bread complexes, hypermarkets, and other businesses that produce large quantities of bread.

Delivery time varies depending on the current order volume. Contact our experts for more information.

The deck oven comes with a 12-month warranty and lifetime after-sales service.

The deck oven can supply steam to a separate proofer or steam room through dedicated piping.

Price of the Fancy Deck Oven

For purchasing and ordering a fancy deck oven, information on the price of the fancy deck machine, information on purchasing conditions for the fancy oven directly from the factory, and also receiving pre-purchase consultation; you can contact our sales experts through the following communication channels:

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com