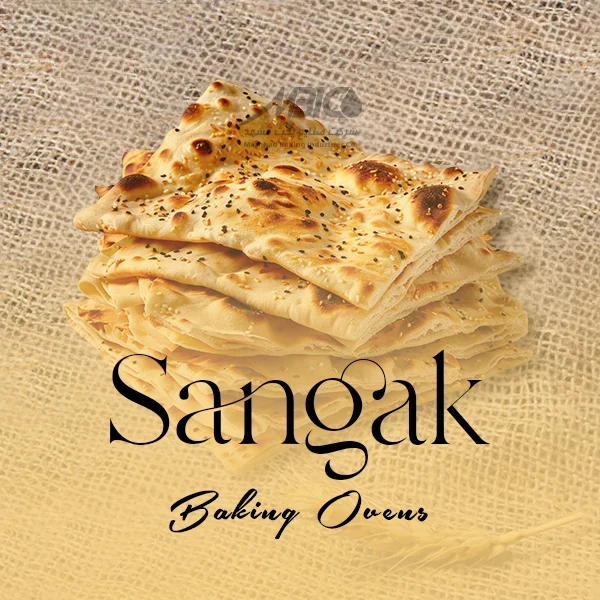

Sangak bakery ovens

Sangak bread, a traditional Iranian flatbread, has held a special place in Iranian cuisine for centuries. Characterized by its oval shape, soft texture, and numerous air pockets, it is often considered one of the most delicious and healthy types of bread. The inventor of sangak bread, Sheikh Baha’i, is a significant figure in Iranian baking history. Given its widespread popularity in Iran, sangak bread is often regarded as the national bread of the country.

Baking sangak bread requires specialized baking equipment and bakery ovens. Sangak baking machines serve as excellent replacements for traditional stone ovens and ensure a hygienic baking environment. These machines come in various models, and the choice of the right equipment plays a crucial role in producing high-quality sangak bread.

Sangak bread can be baked using both automatic and semi-automatic methods. Consequently, sangak baking machines are available in two main categories: automatic and semi-automatic.

Types of Sangak Baking Machine

Automatic Sangak Baking oven

For fully automated sangak bread production, two types of machines are commonly used: automatic tunnel ovens and automatic rotary portable sangak ovens. These machines, along with auxiliary equipment such as dough mixers, dough elevators, automatic dough sheeters, and sesame seed sprinklers, create a fully automated sangak bread production line.

In these machines, water and flour are thoroughly mixed in a specialized dough mixer equipped with a stationary blade. After resting, the dough is transferred to a dough sheeter by an elevator. The dough sheeter evenly spreads the dough onto a bed of textured plates resembling pebbles. The dough is then baked. In tunnel ovens, after baking, the bread is automatically cut to the desired size by an electric tunnel cutter and then transferred to a cooling and collection area. In rotary ovens, a worker is required to manually remove the bread and transfer it to the cooling and collection area.

Semi-Automatic Sangak Baking Machines

For semi-automatic or manual sangak bread baking, a baker is required. Two suitable machine types are tunnel ovens and portable rotary ovens. In this method, after the baker spreads the dough on a sangak paddle, the dough is placed on the baking bed, which consists of textured plates, for baking. Once baked, the bread is manually transferred to the cooling and packaging area by another worker.

Types of Sangak Baking Machines Based on Heating System

Indirect-Fired Sangak Baking Machines: These machines utilize a special heating system, ensuring optimal fuel efficiency and a highly hygienic baking process. Mashhad Baking Industries designs and manufactures three types of indirect-fired sangak ovens in various sizes, improving the quality and efficiency of the sangak baking process.

Sangak Bread Baking Machines from Mashhad Baking Industries

Mashhad Baking Industries, leveraging advanced technology and international standards, has successfully designed and manufactured high-quality sangak bread baking machines. These machines, equipped with cutting-edge technology and premium materials, enable the production of authentic sangak bread with its traditional taste and texture. The sangak bread baking machines from this company are designed to meet the needs of both domestic bakers and Iranians residing abroad. These models are categorized into two main groups, each offering unique features and capabilities for optimal sangak bread production.

Rotary Sangak Machines

As the name suggests, these machines have a rotary design where the sangak dough is baked while rotating within the machine. The baked bread is then manually removed from the machine. This model can be used in both automatic and semi-automatic modes.

Tunnel Sangak Machines

Tunnel sangak baking machines are designed to produce a large number of sangak breads at regular intervals and high speeds, significantly improving production efficiency in the baking industry. These machines utilize advanced automation and mechanical processes to produce sangak bread automatically and consistently. This feature ensures high productivity and quality even with increasing demand, making it valuable for the baking industry’s economy. These machines can also be used in automatic or semi-automatic modes.

This classification helps users select the most suitable sangak baking machine for their specific needs.

Replacing Traditional Sangak Ovens with Machine-Based Ovens: Preserving the Authentic Taste and Shape of Sangak Bread

Replacing traditional ovens with advanced sangak baking machines is a significant step towards modernizing bakeries and ensuring a hygienic baking environment. These machines, with precise temperature and time controls, produce high-quality bread with uniform baking and reduce energy and material waste. Additionally, sangak baking machines offer automation and various settings to adapt to different production needs. Despite these advancements, preserving the authentic taste and aroma of sangak bread remains a challenge, and new technologies can effectively maintain these unique characteristics. Overall, these innovations can help bakers reduce costs, increase efficiency, and provide high-quality bread that meets consumer demands.

Key Features to Consider When Choosing a Sangak Baking Machine

To select a high-quality sangak baking machine, it is essential to be familiar with the important features of this baking equipment. One of the most important factors in this selection is knowing the manufacturer and brand of the baking machine. This information can provide a comprehensive view of the machine’s quality and increase your confidence in the product. Mashhad Baking Industries, the largest manufacturer of automatic and semi-automatic sangak machines in Iran, produces a diverse range of high-quality baking equipment. Choosing the right sangak baking machine is a crucial decision for bakers, and careful consideration should be given to the selection process. Other important features of a good sangak baking machine include:

- Safety

- High efficiency

- Energy efficiency

- Robust and modern design

- Ease of use

- Warranty and after-sales service

Price of Sangak Baking Machines

When purchasing a sangak baking machine, factors such as size, production capacity, baking method, and technology used should be considered to make the best choice based on your specific needs. To inquire about pricing and receive advice on selecting the right baking machine, please contact our sales team.

Contact Us:

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com