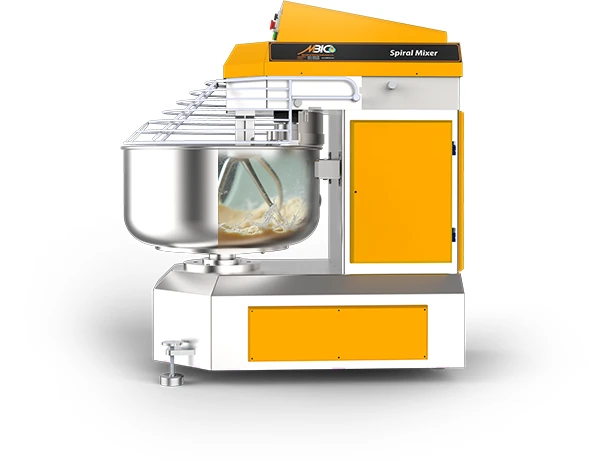

The spiral mixer, also known as a spiral dough mixer or industrial dough mixer, is one of the most modern types of dough mixers for preparing various doughs, especially bread and pastry dough. It uniformly combines raw materials with high speed and excellent quality. Mashhad Baking Industries is the largest designer and manufacturer of various spiral and conventional dough mixers in world.

Introducing the Spiral Dough Mixer

Ideal for Mixing the Bigger Volume of Dough in a Short Time:

Reverse Bowl Rotation and Provides Homogenate Dough Mixture in a Short Time.

The spiral mixer is an advanced type of industrial mixer designed and manufactured for mixing and kneading heavy and sticky doughs, especially bread dough. The spiral machine is recognized as one of the most modern types of dough mixers in the baking industry. Due to its optimal performance and high efficiency, it is considered one of the efficient and advanced bakery equipment for bakeries, pastry shops, and food production factories. Using a spiral mixer improves dough quality and accelerates the production process.

Complete and uniform mixing of dough ingredients is one of the most important factors in achieving high-quality bread and pastries. This process ensures proper distribution of raw materials and helps improve the texture, taste, and shelf life of the final product. The bakery and pastry spiral, due to its complete mixing of dough components and subsequent production of a very uniform dough with a special texture, is one of the best choices for bakeries, confectioneries, and modern pastry shops.

Spiral Mixer with Mobile Bowl used to mix and knead the dough in a short time that provides Homogenate Dough Mixture, recommended as the first solution for Bakeries and Confectioneries. Spiral Mixer operates in Manual and Automatic systems with two programmable timers.

The spiral mixer is equipped with a stainless steel spiral blade that mixes the dough in two directions (clockwise and counterclockwise) at different speeds and precise timing with a vertical rotary motion. The special design of this spiral blade ensures that the dough is kneaded uniformly and can be used for various volumes. Due to the helical design of the blade, this device is also known as a helical mixer. The spiral mixer is equipped with programmable timers that allow adjusting the speed and duration of dough mixing and can be used in both automatic and manual modes.

The spiral dough mixer is equipped with a guard and microswitch that ensures user safety during operation. These guards are designed to prevent unauthorized access to the moving parts of the machine and reduce potential hazards. The microswitches automatically turn off the machine as soon as the guard is opened, preventing any accidents. These features not only guarantee safety but also assure users that they can use the device safely and without worrying about risks.

Types of Spiral Dough Mixers

Spiral mixers are offered in various models. The spiral dough mixer bowl is made of high-thickness stainless steel and is offered in two models:

Automatic Spiral Dough Mixer

In this model of the spiral mixer, users can set the mixing time and speed. After starting, the device automatically shuts off at the end of the set time. Also, in the automatic model, automatic mixing speed change is possible, so that the device automatically changes the mixing speed in different stages, which helps optimize the mixing process.

Manual Spiral Dough Mixer

In this model of the spiral dough mixer, users can manually turn the device on and off and adjust the working time according to their needs and manage the mixing process.

Spiral Dough Mixer with Detachable Bowl:

A spiral with a detachable bowl is a type of industrial spiral dough mixer in which the bowl can be detached from the device. Detaching the bowl can perform dough making, handling, and emptying processes automatically and more efficiently. By combining this feature with automatic conveying systems or production lines, dough preparation and transfer steps can be performed without the need for direct human intervention. This leads to improved production speed, reduced human error, and increased accuracy in process timing.

Spiral Dough Mixer with Fixed Bowl:

In this model of dough mixer, the bowl is attached to the body of the device, which helps with greater strength and stability during operation. The bowl rotates clockwise or counterclockwise and performs the dough mixing process. In this model of the spiral dough mixer, emptying the dough is done manually by human force. This feature is due to the fixed structure of the bowl, which, although it helps with greater stability of the device, requires human intervention to empty the dough.

Features of Industrial Spiral Mixers

- Suitable for dough making in bakeries, pastry shops, and high-capacity bread complexes.

- Sturdy structure: designed with a very resistant chassis and body.

- All-stainless steel spiral arm.

- One-piece stainless steel bowl.

- Powerful motors: using high-quality electric motors.

- Ability to install PLC control system.

- Has the shortest dough making time.

- Silent and vibration-free operation: special design to reduce vibration and noise of the device.

- Two-way rotation: ability to rotate in two directions, right and left.

- Precise timing with automatic and manual adjustment capability.

- Ability to adjust the dough making process speed in two modes, slow and fast.

- Possibility of connecting city water to the device inlet to increase ease of dough making.

- Ability to make dough on a small scale.

- Equipped with wheels for easy carrying and moving.

- Has Iranian national standard.

- Has ISO 9001 certification.

Accuracy and uniformity in dough size

The dough divider divides the dough with equal accuracy, which helps with uniformity of the final product and better shaping.

Increased production speed and mass production capability

The divider speeds up the production process by dividing the dough quickly and evenly and enables mass production.

Reduced need for labor

The divider automates the dough balling process and significantly reduces the need for human labor.

Full compliance with health principles and reduced hand contact

By automating the dividing process, the divider reduces hand contact and helps maintain hygiene and prevent contamination.

Overall improvement of the production process

Using a divider increases efficiency and optimizes the production process, making it an important tool in the baking industry

Increased quality of the final product

Accurate and uniform division of the dough improves the texture and quality of the final product.

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com