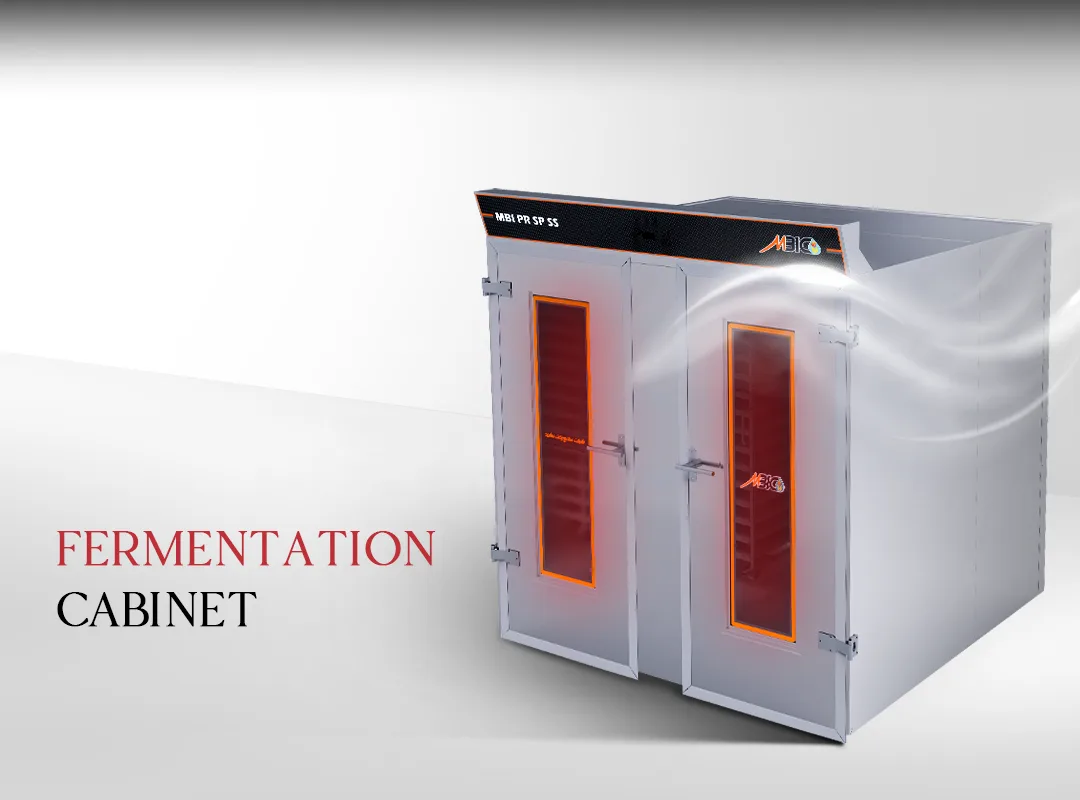

Fermentation Cabinet, Proofing Chamber

A fermentation cabinet, also known as a proofing chamber or proofer, is an essential piece of equipment for industrial bakeries, confectioneries, and any establishment requiring dough resting and fermentation in a humid environment. This equipment is specifically designed for the final fermentation process.

After the dough is shaped, the individual pieces (dough pieces) are placed on trays, which are then loaded onto racks (dough trolleys). These racks are subsequently moved into the fermentation room to undergo the final proofing stage. The proofing chamber creates the necessary conditions, including precise temperature and humidity levels, ensuring optimal dough development.

The processed doughs are transferred into the Fermentation Chamber by means of dough trolley and fermented under controlled environment of heat and humidity, after that the dough is ready for baking. It can be provided as stainless steel or aluminum models depending on the request. All the Fermentation Chambers are completely insulated. It's suitable to use with steam generator. Fermentation Chamber is also called the Fermentation Room, Fermentation Compartment and Fermentation Cabinet.

Steam Supply in the Proofing Chamber

The required steam inside the proofer is supplied either by a steam generator (steam unit) or from the oven itself. If a dedicated steam generator is used, the proofing chamber is equipped with a control system that allows for turning the generator on and off, adjusting temperature and steam levels, and includes a display to monitor the room's temperature.

If the steam is supplied by a large multi-deck oven, the proofing chamber may not require a separate steam generator due to the oven's inherent steam production capabilities. However, if a rotary rack oven is used, the proofer must be equipped with a steam generator and a dedicated control system to maintain the appropriate humidity.

Types of Fermentation Cabinet

Proofing chambers are manufactured in various sizes, and their capacity is determined by the number of racks they can accommodate. MBICO offers proofing chambers with capacities ranging from one to sixteen racks, providing customers with a wide selection to suit their specific production needs. These proofers are built using high-quality materials and advanced technology to ensure maximum performance and durability.

The proofer's body is constructed as a double-walled structure using sandwich panels with either double-sided stainless steel or a combination of stainless steel on one side and galvanized steel on the other. This configuration can be customized based on the customer's preferences. Additionally, the proofing chamber can be manufactured with either single or double doors equipped with tempered glass, allowing for visual monitoring of the fermentation process.

Models and Technical Specifications of Proofing Chambers

MBICO offers a wide range of proofing chamber models to fully meet customer requirements. Each model is designed and manufactured based on specific customer needs and preferences to ensure optimal performance and efficiency for the final dough fermentation. This variety enables industrial bakeries and other dough-related businesses to achieve high productivity and improved product quality by selecting the appropriate proofing chamber model.

Capacity ( 2 Racks)

Dimensions (cm): 215*110*200

Power Consumption (kW): 7

Capacity ( 4 Racks)

Dimensions (cm): 224*208*202

Power Consumption (kW): 7

Features and Capabilities of Proofing Chambers

- Various Dimensions: Proofing chambers can be designed and built in various sizes to meet the production needs of any industrial bakery.

- Construction Materials: Proofers are constructed from durable, specialized materials that can withstand high temperature and humidity conditions. These materials typically include stainless steel, thermal and humidity insulation, and corrosion-resistant coatings.

- Temperature and Humidity Control: One of the key features of a proofing chamber is its ability to precisely control temperature and humidity.

- National Standard of Iran Certified

- One-Year Warranty and Lifetime After-Sales Service

Advantages of Using a Proofing Chamber

In the production of many types of bread, especially flatbreads, challenges such as the absence of final fermentation, insufficient fermentation time, difficulty controlling temperature during hot seasons, and inconsistent temperature and steam distribution are common. Using standard proofing chambers can address these issues and provide optimal conditions for producing high-quality, healthier bread.

Precise Environmental Control

The proofing chamber allows for precise control of temperature, humidity, and steam, which is essential for optimal fermentation.

Reduced Waste

By precisely controlling fermentation conditions, the likelihood of problems such as incomplete or excessive fermentation is reduced, leading to less waste.

Improved Final Product Quality

Precise control of fermentation conditions results in a final product with improved texture, flavor, and aroma.

Accelerated Fermentation Process

Providing ideal conditions accelerates the fermentation process, leading to increased productivity and reduced production time.

Increased Bread Volume

Suitable fermentation conditions increase the volume of the bread and improve its appearance.

Precise Monitoring

Display and control systems allow for easy monitoring of the fermentation process and necessary adjustments

Price and Warranty

For information on proofing chamber prices, direct factory purchase options, and pre-purchase consultation, please contact our sales experts through the contact information provided below.

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com

Frequently Asked Questions (FAQs) about Fermentation Cabinet

Our customers refer to them by various names, including:

- Proofing Oven

- Steam Room

- Final Fermentation Chamber

- Proofer

- Proofing Cabinet

Proofing chambers are ideal for:

- bakeries

- Large-scale bakeries producing traditional breads

- Confectioneries

- Any establishment requiring dough resting and fermentation in a humid environment.

They are suitable for various dough types, including those used for bread, pastries, and other baked goods that require proofing.

Installation is straightforward. Simply place the unit in the desired location. No special installation work is typically required.

Proofing chambers with steam units can be manufactured for either single-phase or three-phase power, depending on the customer's needs and available electrical supply.

The body of the proofing chamber is constructed from sandwich panels. These panels are either double-sided stainless steel or a combination of stainless steel on one side and galvanized steel on the other.

MBICOs offers two main types of proofing chambers:

- Proofing chambers equipped with a steam unit.

- Proofing chambers without a steam unit (designed to utilize steam from another source, such as a multi-deck oven).

We offer a wide range of sizes, with capacities ranging from one rack to sixteen racks. Units can be manufactured as single, fully assembled units or in modular sections for easier transport and assembly on site.

While our standard proofing chambers are manufactured as single, fully assembled units, we can also produce multi-section units upon customer request. These are sometimes referred to as "bolt-together" proofing chambers.

- Grounding connection.

- Connection to a power outlet.

- Turning on the conveyor oven.

- Setting the temperature and conveyor belt speed.

- Start baking.