The dough mixer, also known as a dough kneader or dough mixing machine, is a crucial piece of equipment for dough preparation in bakeries, confectioneries, and pastry shops. Mashhad Baking Industries Company is the largest manufacturer of various dough mixers for diverse applications.

Product Introduction: Bakery Dough Mixer

The dough mixer, also known as a dough kneader or dough mixing machine, is a crucial piece of equipment for dough preparation in bakeries, confectioneries, and pastry shops. Mashhad Baking Industries Company is the largest manufacturer of various dough mixers for diverse applications.

The dough mixer is a crucial and practical piece of equipment designed for efficient and uniform mixing and kneading of various dough types in a short time. Dough mixers have a wide range of applications, primarily used for blending the initial ingredients of dough. A prominent application is in bakeries, where the dough mixer is considered one of the most essential pieces of equipment, a core requirement for any baking operation. Consequently, dough mixers are commonly referred to as "bakery mixers," "dough kneading machines," or "dough kneaders" among users.

Beyond bakeries, dough mixers find application in bread production complexes, confectioneries, fast-food restaurants, culinary schools, and even residential settings. A typical dough mixer comprises a mixing bowl (also known as a pot or vat), a beater or arm with an angled design, a base, and a motor. The angled design of the beater ensures optimal ingredient incorporation and blending, leading to improved dough quality and uniformity.

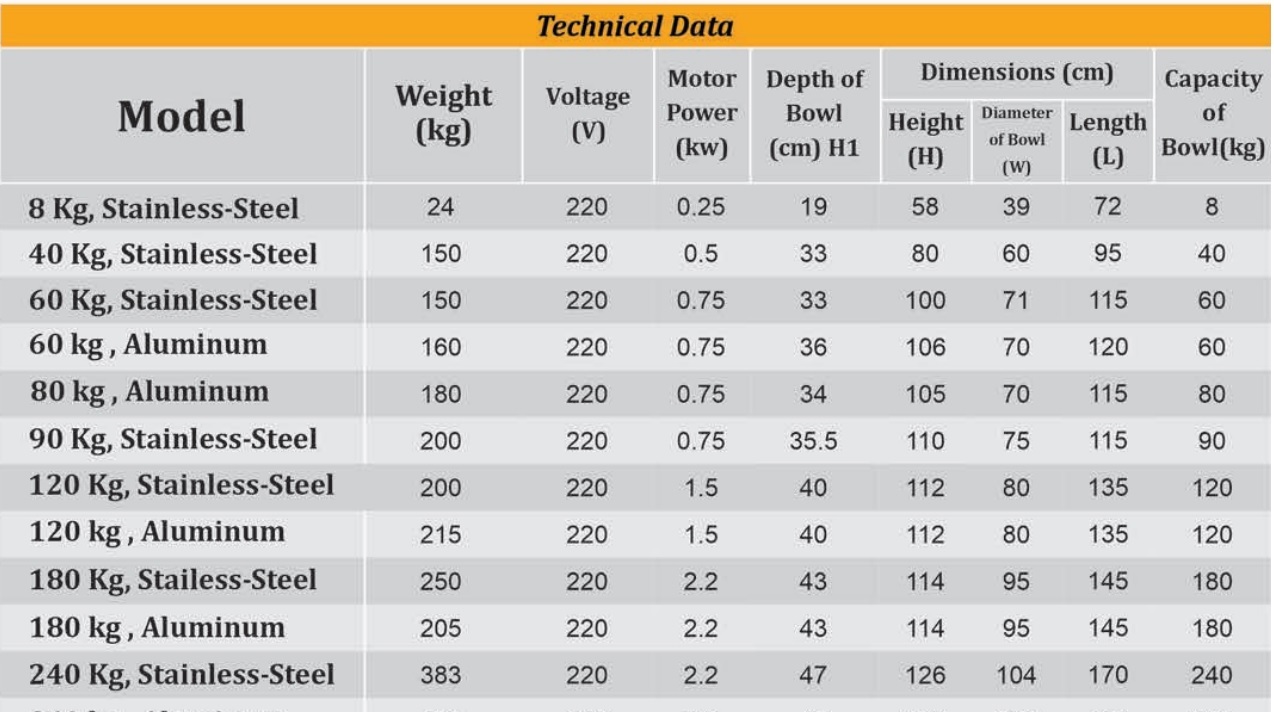

Dough Bowl is made of Aluminum and Stainless-Steel (Food Grade) as per the request Can be produced with Safety Lid which is equipped with Micro Switch as per the needs.

Bakery Mixer Beater Specifications

The beater, also referred to as an "arm" or "paddle," is a key component of the dough mixer/kneader and is typically constructed from stainless steel or aluminum with a stainless steel cladding. This beater is responsible for mixing and kneading the dough. Depending on the capacity of the kneader, it is designed with two or three arms. Generally, smaller capacity kneaders are equipped with a three-arm beater, while larger capacity kneaders utilize a two-arm configuration. Selecting the correct beater significantly impacts the performance of the dough kneading machine.

Bakery Mixer Bowl Specifications

The bowl is a critical component of the dough kneader, manufactured in various capacities and from both aluminum and stainless steel with varying thicknesses. The bowl rims can be produced in two shapes: rounded or straight. The kneader capacity is determined such that half is allocated to water and the other half to flour. For instance, if the kneader capacity is 100 kg, one can use 50 kg of water and 50 kg of flour. This division ensures the correct ratio of ingredients for dough preparation and contributes to the final dough quality. Therefore, considering the capacity and its suitability for production needs is crucial when choosing a dough kneader.