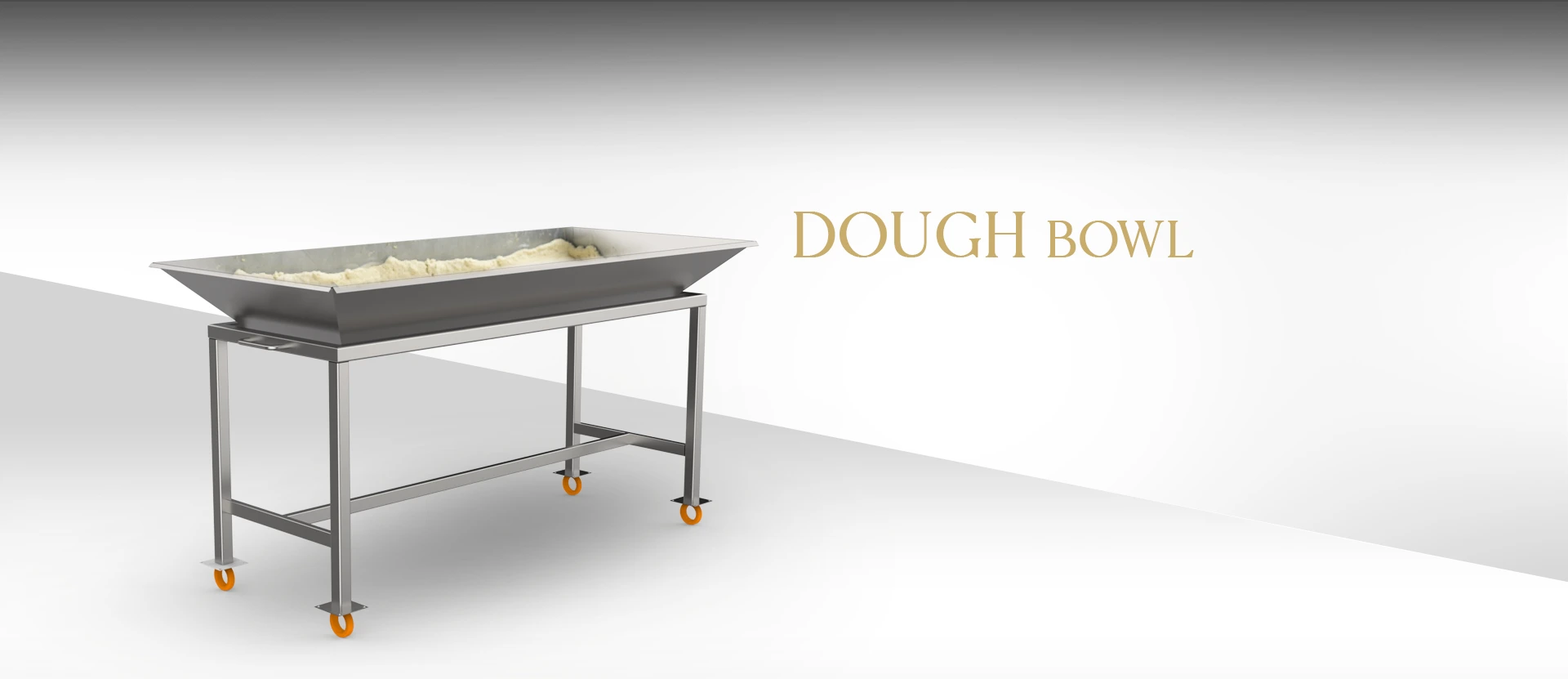

The dough bowl, also known as a dough tub, dough vat, or stainless steel dough container, is a practical piece of equipment used for transporting and initially resting dough in bakeries, confectioneries, and any place where initial dough fermentation is required.

Introduction to the Stainless Steel Dough Bowl

The dough bowl is a highly practical accessory for transporting, storing, and resting dough in bakeries, confectioneries, pastry shops, and any place that works with dough. Using a dough bowl helps improve the quality of the final product because it enables the initial fermentation process. Dough resting, or initial fermentation, when done correctly and sufficiently, increases the dough's volume, improves its texture, and ultimately produces a product with a crispy crust and a well-baked interior. Another use of the bakery dough bowl, in addition to transporting, storing, and resting dough, is emptying the dough mixer or dough kneader to prepare new dough.

Due to the widespread use of the dough bowl, this product is also known by other names, such as:

Bakery dough bowl, dough tub, bakery tub, dough vat, dough resting vat, bakery container, stainless steel tub, dough resting tub, dough container, dough transport tub, dough resting container, stainless steel container, bakery container, bakery vat, stainless steel vat, industrial stainless steel vat, dough mixer container, bakery dough container, dough mixing container, and dough transport tank.

The stainless steel dough bowl has a sturdy steel base equipped with four high-load-bearing wheels, which makes transporting and moving the dough easy. Two of the base wheels are simple, and the other two are designed with brakes so that the bowl remains stationary during operation and prevents unwanted movement.

The dough bowl is made of food-grade stainless steel, a widely used and popular material in the baking industry, in one piece. Features such as corrosion resistance, high durability, and ease of cleaning make stainless steel very suitable for use in dough bowls. Stainless steel dough bowls are easily washable and can be used continuously in the initial fermentation process.

Dough bowls are produced in two shapes: rectangular and round, each with its own specific applications. The round bowl, also known as a dough pot, is usually suitable for use in confectioneries or for looser doughs such as sangak dough and is used for resting and initial fermentation of the dough. The circular design with high walls creates a uniform environment for fermentation, which helps improve the quality of the dough and increase its volume. While the rectangular bowl is more suitable for bakeries.

Technical Specifications of the Dough Bowl

At Mashhad Baking Industries, the dough resting bowl is produced in two models: round bowl and rectangular bowl, with various dimensions and dough capacities, with wheels, made of food-grade stainless steel according to customer orders.

50 kg Dough Bowl

Dimensions (cm): 93*54*68

Bowl Depth (cm): 30

Sheet Thickness (mm): 0.5

Approximate Weight (kg): 16

100 kg Dough Bowl

Dimensions (cm): 86*54*102

Bowl Depth (cm): 30

Sheet Thickness (mm): 0.5

Approximate Weight (kg): 18

180 kg Dough Bowl

Dimensions (cm): 96*58*156

Bowl Depth (cm): 29

Sheet Thickness (mm): 1.25

Approximate Weight (kg): 24

120 kg Dough Bowl

Dimensions (cm): 90*63*90

Bowl Depth (cm): 50

Sheet Thickness (mm): 1.25

Approximate Weight (kg): 63

Features of the Stainless Steel Dough Bowl

- Suitable for transporting and moving dough

- Suitable for the initial fermentation process

- Suitable for use in bakeries, confectioneries, pastry shops, etc.

- Tank material: Food-grade stainless steel

- Equipped with four wheels (two with brakes and two simple)

- Sturdy steel base

- Has Iranian national standard

- Has ISO 9001 certification

Price and Warranty

For more information about purchasing a dough bowl and to inquire about the prices of various types of bakery dough bowls, as well as to place an order for the production of the required bowl, you can contact our sales experts through the following communication channels.

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com

Frequently Asked Questions about Dough Bowls (Dough Tubs/Dough Vats)

Dough bowls are known by various names, including: dough tub, dough vat, dough container, and dough trough.

The bowl (or container) itself is made of food-grade stainless steel, while the base is made of steel.

The thickness of the sheet metal used in making the dough bowl varies based on its capacity. For higher capacities, a 1.25 mm thick sheet is used, and for lower capacities, a 0.5 mm thick sheet is used.

Bakery dough bowls can be produced in various capacities, but the standard capacities are 100 kg and 180 kg. Other sizes are available upon request to meet specific needs.

Yes, the bakery dough bowl has wheels for easy transport and movement of the dough. It includes two fixed wheels and two swivel wheels with brakes.

Dough bowls are used for transporting, storing, and resting dough in bakeries, confectioneries, and pastry shops. This equipment aids in the initial fermentation process and helps produce a higher quality final product. It is also used to empty the dough mixer or kneader for preparing new batches of dough.

Dough bowls are produced in two main models based on their application: round dough bowls (often called dough pots or vats) and rectangular dough bowls (often called dough tubs or troughs).

Yes, the bakery dough bowl can be easily detached from its base.