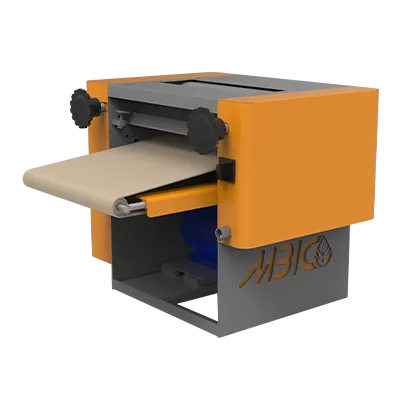

Conveyor Pizza Oven, often called a Tunnel Pizza Oven designed and produced for cooking Pizza, Hot Dog, Lasagna (Lasania), Steak, Kebab, Chicken & Hamburger quickly and easily with perfect results; Pizza Oven is the best choice and solution for Restaurants, Fast Foods, Hotels and Hypermarkets.The major specifications of Conveyor Pizza Oven are Homogeneous, Good Uniformity and High Quality of Baking as well as high cooking capacity.

The Conveyor Pizza Oven, with a fully stainless steel body, is an ideal choice as a mini oven for baking various types of pizza, chicken, kebabs, and other fast food items to perfection. This oven is highly popular due to its ease of use and fast cooking time for a variety of foods, especially in fast food outlets and both small and large restaurants. Mashhad Baking Industries, a reputable manufacturer, produces various mini ovens and industrial ovens for use in restaurants, fast food outlets, hotels, and hypermarkets.

Recommended for Baking kinds of Pizza, Steak, Kebab, Chicken & Burgers Quickly and Easily

The Conveyor Pizza Oven is an excellent tunnel mini oven for food preparation in restaurants, fast food outlets, hotels, and hypermarkets, capable of baking various items such as pizzas, hot dogs, lasagna, steaks, kebabs, chicken kebabs, wings, drumsticks, and different types of burgers (including charcoal burgers), and more. Traditional ovens often face issues like localized and surface burning while leaving the interior of the product raw, loss of moisture, and food drying out during cooking, all of which result in decreased quality and customer dissatisfaction. Therefore, providing high-quality food with excellent cooking results has become a common challenge for restaurants, fast food outlets, hypermarkets, and hotels.

Mashhad Baking Industries’ rail oven provides an ideal solution to this challenge. The mini rail oven ensures even cooking, allowing the food’s interior to be fully cooked without losing moisture or drying out. For example, chicken kebabs cooked in this oven will be juicy, thoroughly cooked, and free from burns or undercooking. The rail oven has a high production capacity and efficiency, capable of cooking 150 single pizzas per hour. This modern rail oven, with its smart design and reliable performance, allows you to offer the best meals to your customers, even in small, high-traffic spaces.

Due to its diverse applications in various locations, this oven is known by many names, such as pizza and chicken rail oven, mini rail pizza oven, mini tunnel oven, mini chicken oven, tunnel pizza oven, rail oven machine, tunnel rail oven, rail pizza maker, and small rail oven. However, because it is most commonly used for baking pizzas, it is primarily referred to as the "pizza rail oven."

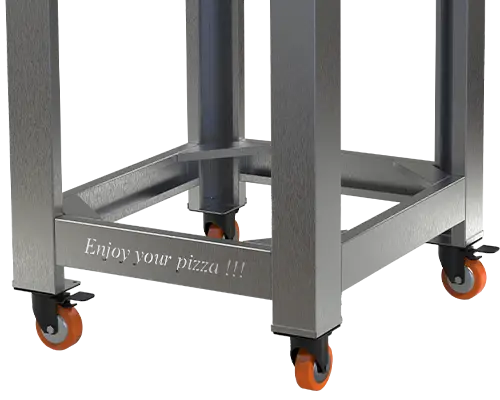

The mini rail oven features a separate stainless steel base equipped with lockable wheels, ensuring easy mobility and stability of the oven. The wheels are lockable, allowing you to effortlessly move the rail oven to any desired location and securely lock the wheels to keep it in place once it reaches the intended spot. This feature is highly useful and efficient, enabling you to manage your space in the best possible way.

HEATING SYSTEM

The Conveyor Pizza Oven uses a convection heating system for cooking products. The convection heating system is an advanced method in cooking technology. In this system, hot air generated by the burner is evenly distributed inside the rail oven by a fan, allowing the heat to be transferred uniformly to the cooking products and preventing localized or surface burns. The advantages of the convection heating system include uniform heat distribution, even cooking without surface or localized burns, fast cooking times, retention of moisture in the food, and prevention of drying out.

CONTROL BOX

The rail oven is equipped with a control panel. The presence of the control panel in this mini oven is an important and efficient feature, allowing adjustments for settings such as cooking time, conveyor belt speed, and oven temperature based on the type of product. This feature can help improve the cooking quality of products and achieve better results in food preparation.

The ability to increase the temperature of the rail oven to 300 to 350 degrees Celsius is an important feature that helps improve the cooking process. This temperature range is generally ideal for cooking various foods, including chicken, pizza, kebabs, and more.

Advantages of the Rail Oven

- Simultaneous cooking of multiple different products

- Complete, high-quality, and uniform cooking of products while preserving their natural taste and aroma

- Easy movement and relocation of the device

- Ability to store 10 different cooking presets in the rail oven control panel

- Optimized energy consumption (fuel and electricity) with no environmental pollution during cooking

- Ability to adjust the time and conveyor belt speed

- Ability to set and control the temperature automatically and electronically

- Equipped with an automatic fan system for uniform heat circulation, with a one-year warranty

- 10 years of after-sales service

Features of the Rail Oven

- Full stainless steel construction

- Equipped with a glass window for product inspection and monitoring during cooking

- Separate base from the rail oven

- Equipped with an automatic shut-off system

- Equipped with lockable wheels

- Ability to cook products in trays within the cooking chamber

- Ability to cook products on the conveyor system

- Equipped with a smart system, timer, and alarm to signal the end of cooking, and certified with the national standard mark

- international ISO certification

Models and Technical Specifications of the Conveyor Pizza Oven

To provide the best performance and results for customers, the mini rail oven from Mashhad Baking Industries is available in one model and two sizes. The pizza rail oven is produced in single-row and double-row configurations. The main fuel for the rail oven is either city gas or gas cylinders, and the electrical power required for its control panel is single-phase.

MBI TCG C 50

Dimensions: 137*105*171

Device weight (kilograms): 170

Cooking chamber dimensions: 49*105*170

Cooking chamber power (kilowatts):0.8

Voltage 220

Rail width (centimeters): 50

Heating power (kilocalories/hour) 16000

MBI TCG C 68

Dimensions: 137*127*190

Device weight (kilograms): 190

Cooking chamber dimensions: 49*105*170

Cooking chamber power (kilowatts):0.8

Voltage: 220

Rail width (centimeters): 68

Heating power (kilocalories/hour) 16000

Conveyor Pizza Oven FAQs

The rail oven has a convection heating system.

The fuel used in the mini rail oven can be either city gas or gas cylinders. Additionally, the mini rail oven is produced in a single-phase configuration.

The production capacity and efficiency of the rail oven are high, as it can bake 150 single-serving pizzas per hour.

The mini rail oven can bake various products including pizza, hot dogs, lasagna, steak, kebabs, chicken kebabs, chicken wings and drumsticks, various burgers (including charcoal burgers), and more.

Due to the various applications of the fancy oven, this product is known by different names such as: pizza rail oven, chicken rail oven, mini pizza rail oven, mini rail oven, mini tunnel oven, mini chicken oven, tunnel pizza oven, rail oven device, tunnel rail oven device, rail pizza oven device, and small rail oven.

Due to the number of pending orders in the production queue, the manufacturing and delivery time of the mini rail oven may vary. For more information, you can contact our sales experts.

The rail oven can be used in restaurants, fast food chains, hotels, and hypermarkets.

The installation and setup of the pizza rail oven is very easy. You can install and set up this mini oven correctly and easily using the installation manual that was sent to you along with the product.

- Grounding the oven

- Connecting to the power outlet

- Turning on the rail oven

- Adjusting the temperature and conveyor speed

- Starting the baking process

The warranty is for one year, and the after-sales service is lifetime.

Price of the rail oven.

To inquire about the price of the pizza rail oven, learn about the different types of rail ovens, get information on purchasing directly from the factory, and receive consultation before making a purchase, you can contact our sales experts through the following communication channels:

Online chat

7*24

We are ready to assist you

In-person visit.

Factory: Kilometer 22, Asiayi Highway, Beginning of Mohammadabad Qaim Maqam Road, Mashhad

Head Office: No. 579, Molk al-Shu'ara Bahar Street, Between Bahar 12 and 14, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

Email:

To receive advice and contact our sales experts, please send your request via email.

mbi@mbico.com