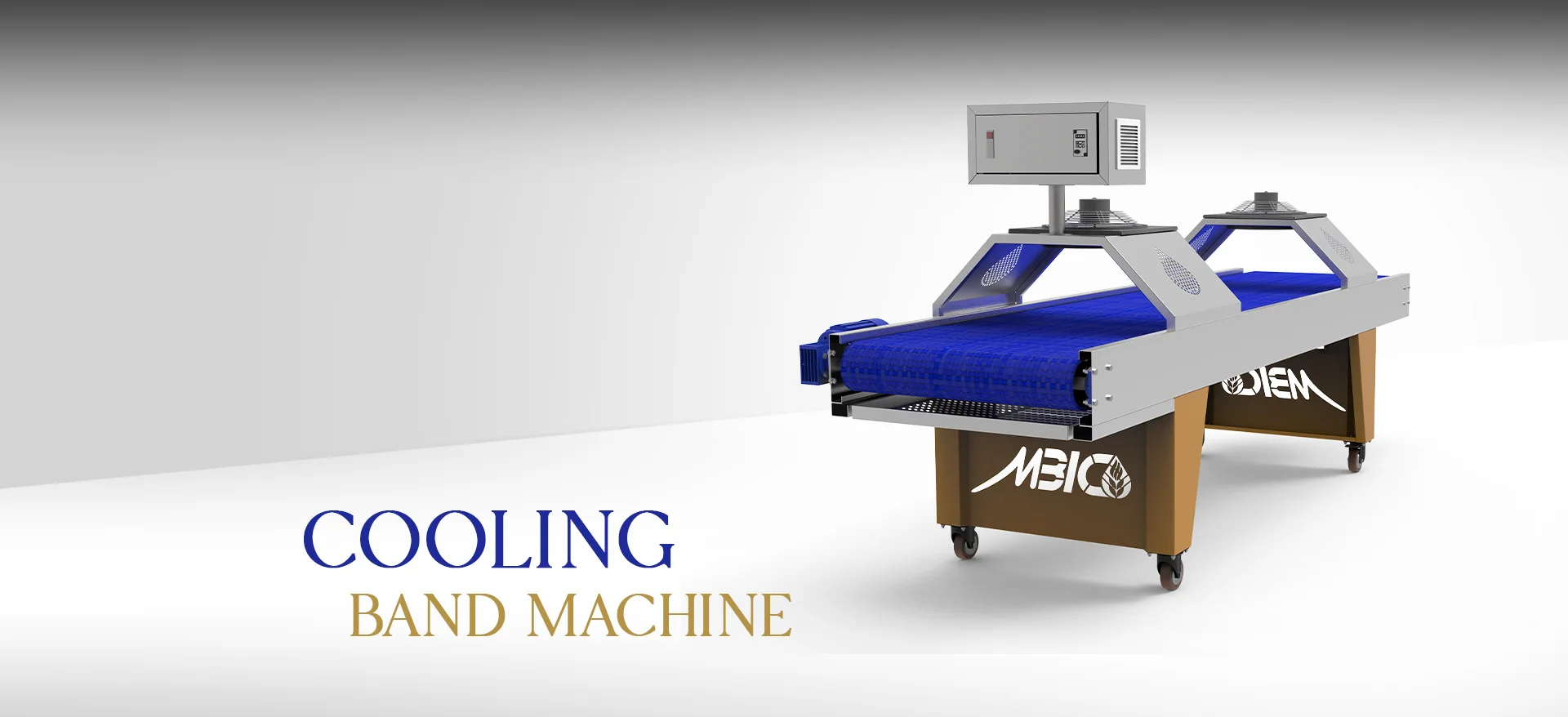

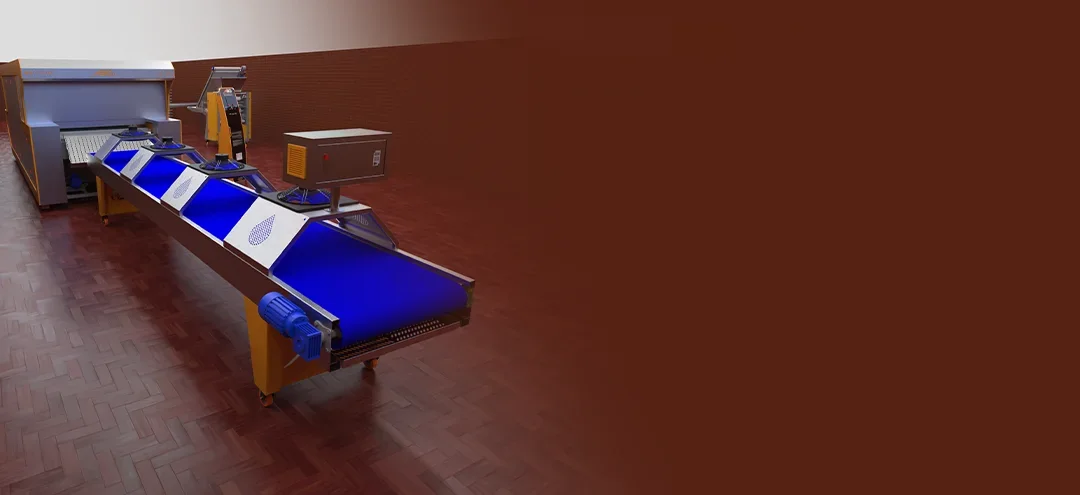

The automatic cooling band machine, also known as an automatic cooler, is an industrial equipment suitable for cooling bread and baked products without manual handling and transferring them to the packaging stage. Mashhad Baking Industries is the largest manufacturer and seller of bakery, bread complex, and confectionery equipment in the world.

Introducing the Automatic Cooling Band Machine

The cooling band is one of the auxiliary and very effective equipment in the food production and preservation industry, especially for bread. Utilizing modern and advanced technologies, the cooling band provides optimal conditions for hands-free cooling, thereby preserving the freshness of food products, including bread, pastries, and other food items, in a completely hygienic manner.

The cooling band is designed in the shape of a tunnel, where products enter from one side and exit from the other after cooling. For this reason, this device is also known as a "tunnel automatic cooler" and "meter cooler." The meter cooler transfers the cooled products to the final packaging stage. Cooling the product and then packaging it leads to maintaining freshness and quality, increasing shelf life, optimizing humidity control, and consequently reducing raw material waste and improving the profitability of producers. These are among the advantages of using a tunnel cooler.

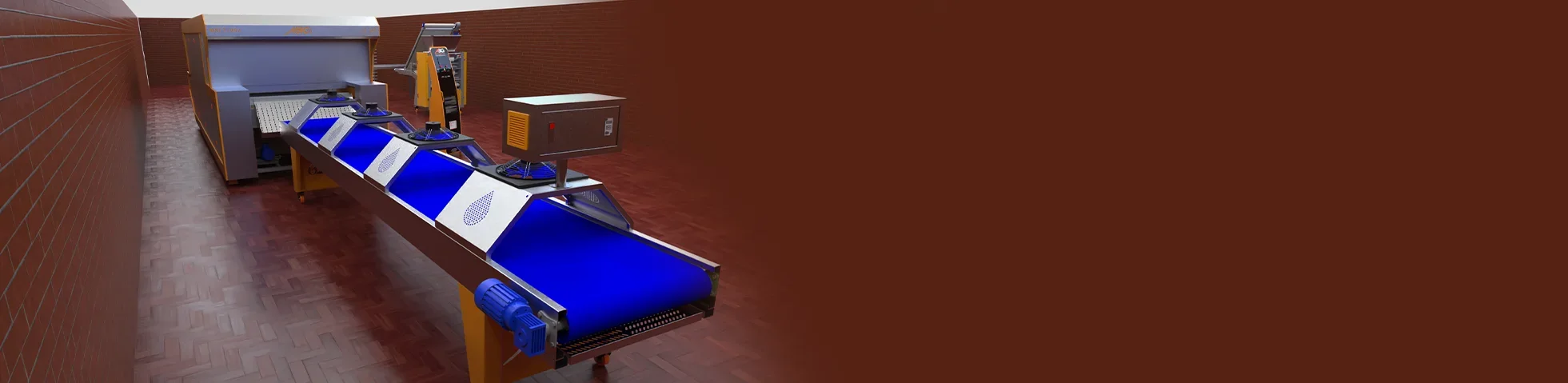

Bread Cooling Conveyor Machine is the type of Conveyor that used for Cooling of Bakery Products; this system can be located at the end of Automatic or Semi-Automatic Tunnel Bakery Oven for Cooling of the Baked Products, then transfer the products to Packaging Process. Cooling operation is done by means of fans and conveyor speed is adjustable by operator.

The Machine is designed and produced by considering the product size and production capacity according to the needs. Transporting the Bakery Products to Packaging Process without Hand Working

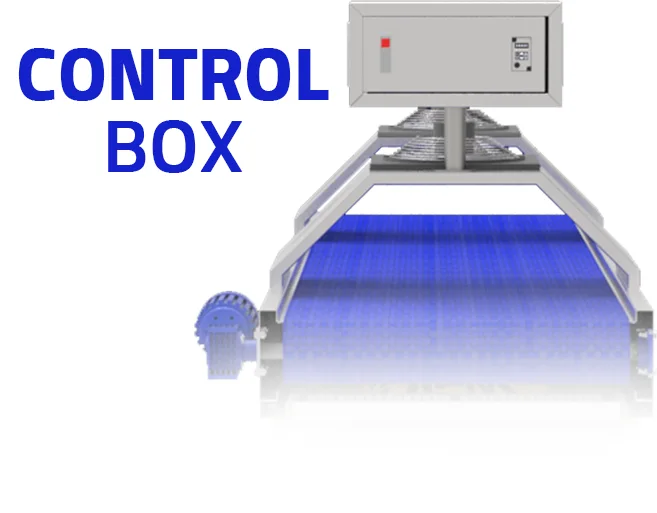

Automatic Cooling Band Control System

The automatic cooling band machine has a control panel that performs all necessary actions and controls, including turning the fans on and off and adjusting the conveyor belt speed. The power required for the portable rotary oven is single-phase.

Automatic Cooling Band Machine Models and Technical Specifications

At Mashhad Baking Industries, the cooling band machine is designed and manufactured in various longitudinal and transverse dimensions. The width of the cooling band is determined based on the width of the baking machine that precedes it and can be offered to customers in one, two, or three rows. Cooling bands are also very diverse in length; they start from 2 meters in length and can be increased according to the needs and production space of esteemed customers.

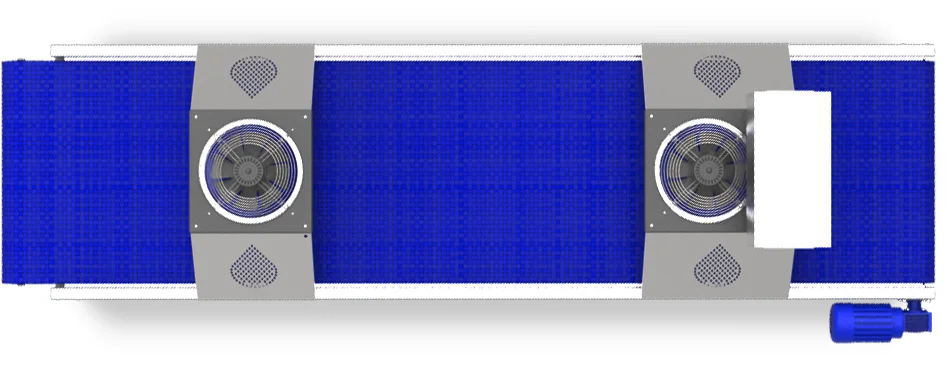

The tunnel cooler is equipped with several "continuous duty blower" fans, which, with continuous and efficient operation, help improve the cooling process. The number of fans installed is determined based on the length of the cooling band to provide complete and uniform airflow coverage along the tunnel. The tunnel cooling belt is made of a modular belt. The modular belt is a special food-grade standard plastic that is abrasion-resistant, corrosion-resistant, and washable. The cooling belt is also equipped with an inverter so that the belt speed can be adjusted as needed.

The chassis body, cooling fan bases, and product collection basket are designed entirely of stainless steel, while the bases of the meter cooler chassis are made of iron with a polyurethane paint coating. The cooling band is also equipped with braked wheels for easy transport and movement.

2-Meter Cooling Band

Dimensions: 150*110*217

Belt Width (cm): 75

Modular Belt

Number of Fans: 2

Motor Power (kW): 0.37

Power Voltage (V):220

3-Meter Cooling Band

Dimensions: 150*110*317

Belt Width (cm): 75

Modular Belt

Number of Fans: 2

Motor Power (kW): 0.37

Power Voltage (V):220

4-Meter Cooling Band

Dimensions: 150*110*417

Belt Width (cm): 75

Modular Belt

Number of Fans: 3

Motor Power (kW): 0.37

Power Voltage (V):220

5-Meter Cooling Band

Dimensions: 150*110*517

Belt Width (cm): 75

Modular Belt

Number of Fans: 4

Motor Power (kW): 0.37

Power Voltage (V):220

6-Meter Cooling Band

Dimensions: 150*110*617

Belt Width (cm): 75

Modular Belt

Number of Fans: 4

Motor Power (kW): 0.37

Power Voltage (V):220

Capabilities and Features of the Automatic Cooling Band

- Equipped with inverter

- Steel bases

- Modular belt material

- Ability to cool various products

- Stainless steel exterior

- Equipped with blower and extractor fans

- Equipped with braked wheels

- Adjustable belt speed

- Has Iranian national standard

- Has ISO 9001 certification

Advantages of Using an Automatic Cooler

Cooling Bread and Other Baked Products

The cooling band ensures that bread and baked products cool faster and more evenly, preserving their quality.

Maintaining the Quality of Bread and Other Baked Products

Using an automatic cooler helps maintain the crisp and soft texture of products and prevents them from becoming doughy.

Preventing Bread and Other Baked Products from Sweating

By creating airflow, the meter cooling band prevents bread and other products from sweating and becoming soggy.

Reducing Waste of Bread and Other Baked Products:

Cooling products with the cooling band prevents them from deteriorating and spoiling prematurely, reducing waste.

Increasing the Shelf Life of Bread and Other Baked Products:

By reducing excess moisture, the shelf life of products is increased, and the chance of mold growth is reduced.

Maintaining Freshness, Flavor, and Appearance:

The cooling band allows products to cool while maintaining their original shape and texture, preserving their flavor and freshness.

Price and Warranty

To inquire about the price of the automatic cooling band machine, purchase conditions for the bread tunnel cooler, and receive consultation regarding the selection of the best automatic cooler, you can contact the sales experts of Mashhad Baking Industries through the following contact methods.

Online Chat

24/7 Customer Support

We are ready to assist you 24 hours a day, 7 days a week.

In-Person Visit (Office/Factory Locations)

Factory: Mashhad, Asiaei Highway, Km 22, Beginning of Mohammadabad Ghaem Magham Road

Head Office: Mashhad, Malekolshoara Bahar St., Between Bahar 12 and 14, No. 579

Phone Calls (Contact Numbers)

Factory:

+985132464090

Head Office:

+985138583180

Get in Touch

To receive consultation and connect with our sales experts, please submit your request through the Email below.

mbi@mbico.com

Frequently Asked Questions about the Automatic Cooling Band

Its primary function is to cool bread and automatically transfer it to the packaging stage.

Bread cooling rail

Automatic bread cooling band

Meter bread cooler

Automatic bread cooling band

Automatic bread cooler

Yes, it has the Iranian National Standard and ISO 9001 certification.

The automatic cooling band, also known as the automatic bread cooler, comes with an installation and setup manual, and after-sales service is provided by our technicians.

The automatic cooler is produced in one model with various sizes. The width of the cooling band is determined and selected based on the baking machine that precedes it in the production line to create greater coordination and efficiency.

This practical equipment is used for cooling various baked products in the food industry. The most common application of the cooling band is in automatic bread production lines. In these lines, the cooling band is placed after the tunnel baking machine to cool the sliced bread and transfer it to the packaging stage.

To inquire about the price of the meter bread cooler, please contact the sales experts at Mashhad Baking Industries.

One-year warranty and lifetime after-sales service.