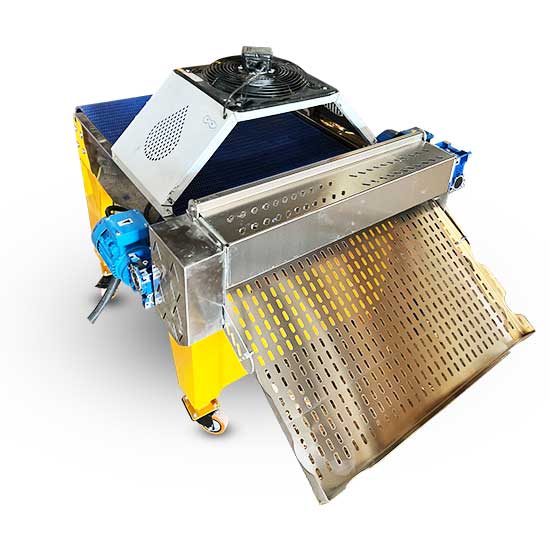

The Tunnel Baking Oven, also known as the "7800 Tunnel Oven," from Mashhad Baking Industries, is the best baking oven in the field of automatic bakery equipment. The tunnel oven is designed for fully automatic baking of traditional breads without manual intervention and has the capacity for mass production of packaged breads. Mashhad Baking Industries is recognized as the largest manufacturer of automatic and semi-automatic bread baking machines in Iran and, by offering this machine, meets the diverse needs of bread producers in the best possible way.

Introduction to the Tunnel Bread Baking Oven

The tunnel bread baking machine, as a prominent innovation in the bakery oven industry, is designed and developed with the aim of increasing production capacity, reducing manual intervention, and improving the bread baking process. The tunnel bakery machine of Mashhad Baking Industries, with a beautiful appearance and unique performance, uses advanced technologies and up-to-date global standards and offers unparalleled quality. Utilizing a 100% indirect heating system, the tunnel baking machine has the capability to bake various types of traditional Iranian breads, including soft Lavash bread, dry Lavash bread, Barbari bread, Taftoon bread, and Sangak bread with excellent quality.

Due to its advanced control system, this baking machine, in addition to its use in the bread baking process, can be used as a baking tunnel in various fields of the food industry. Therefore, it can be used for various other applications such as pencil drying, par-baking pizza dough, and other applications in various industries.

In the construction of the tunnel oven, the best raw materials are used, including stainless steels, high-quality alloys, and high-density insulation.

These materials, due to their extraordinary strength in harsh working conditions, guarantee the optimal performance of the machine and, in addition to increasing efficiency, lead to a long useful life of the baking machine and improve its long-term reliability.

As the name of this baking machine suggests, the tunnel oven is designed in the shape of a tunnel. After preparing the baking tunnel, the bread dough is placed on the baking bed and on the special tunnel belt and is guided to the baking tunnel to begin the baking process. The material of the tunnel bakery machine belt is designed and produced in various ways depending on the customer's needs and the type of bread produced. This belt can be made of galvanized wire mesh, stainless steel, cast iron, or steel. When using cast iron or steel belts, its design is based on the type of bread produced and can be made smooth, perforated, or with raised surfaces to suit the baking process and desired quality.

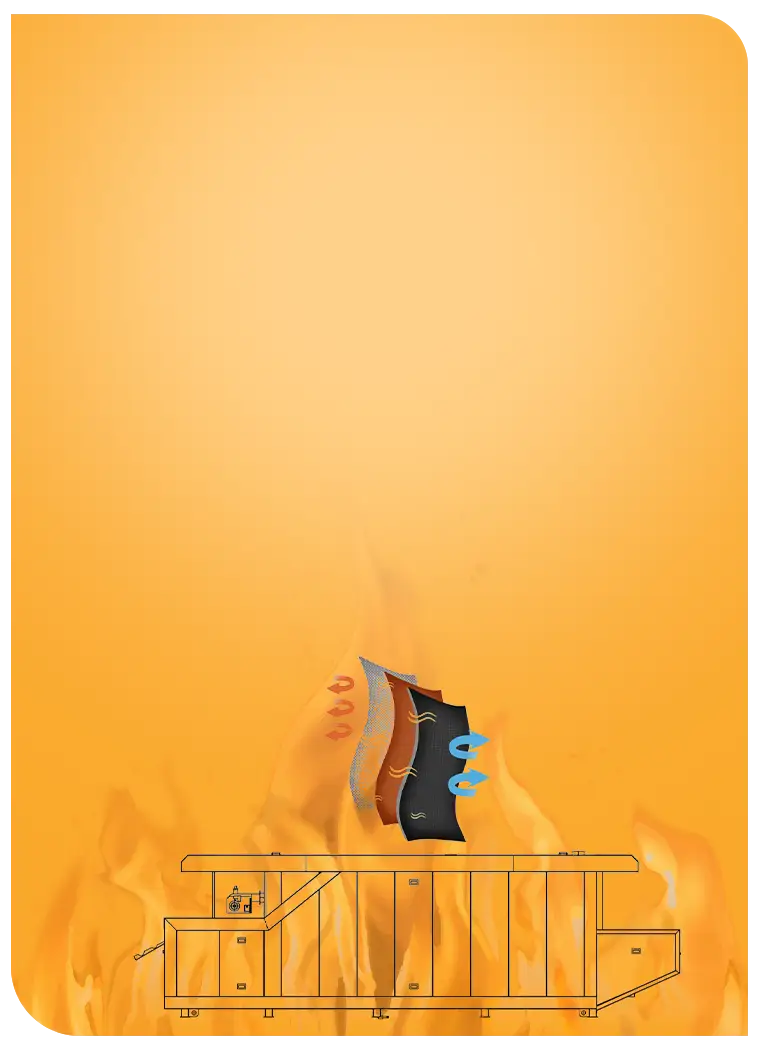

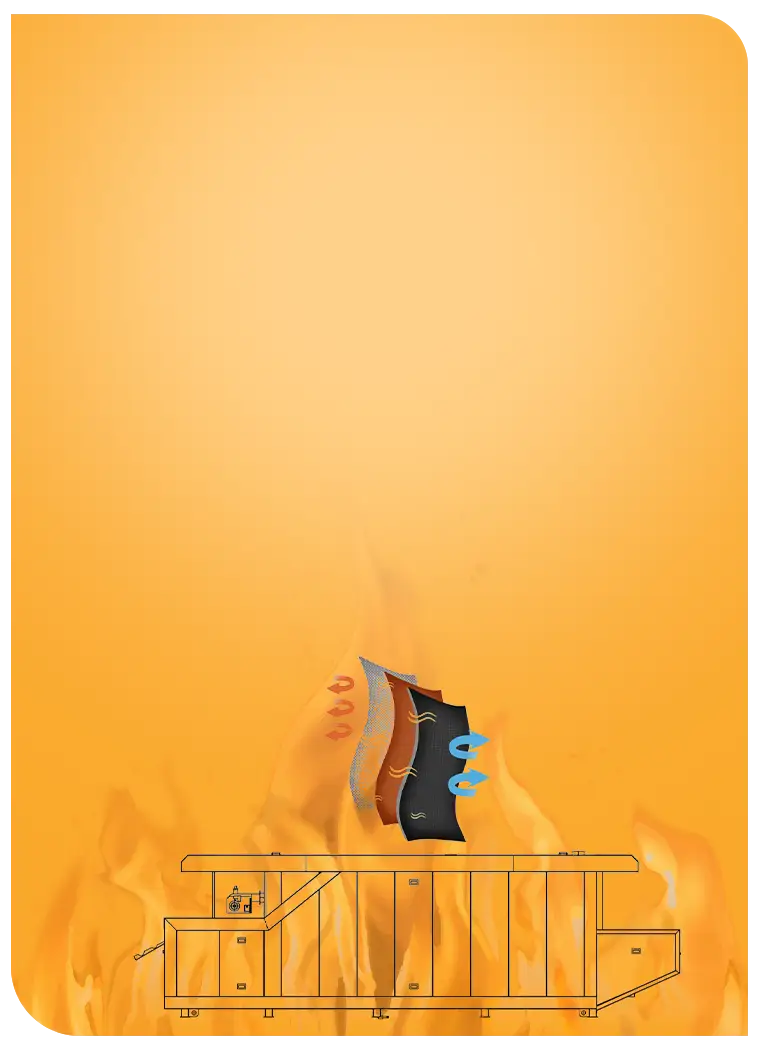

The tunnel bakery machine is equipped with a three-layer insulation system, which plays an important role in optimizing the machine's performance. This insulation system, by maintaining the internal temperature of the machine and precisely controlling the baking process, significantly reduces fuel consumption and prevents the surrounding environment from heating up. As a result, undesirable heat transfer is prevented and the optimum temperature for the baking process is continuously maintained. This feature, in addition to increasing efficiency, improves performance and reduces energy costs.

Equipped with Inverter, Thermometer, and Emergency Stop

One of the outstanding features of the tunnel bakery machine is that the baking tunnel is equipped with an inverter and a thermometer. The inverter allows adjusting the belt speed and controlling the tunnel temperature (separately for top and bottom temperatures). In this way, the bread baking process is easily managed and the possibility of preparing bread with the desired quality is precisely provided.

To increase user safety, the tunnel machine is equipped with an emergency stop button. This button is installed at the dough inlet so that in case of any problem or need for an immediate stop, the user can quickly stop the machine.

Tunnel Oven for Automatic or Semi-Automatic Baking

The tunnel oven, with the ability to be used in two ways: automatic baking (without the need for a baker) and semi-automatic baking, offers extensive possibilities in the baking industry, especially bakeries. This feature provides high flexibility and allows manufacturers to choose the most suitable baking method depending on the type of products and their needs. This variety in baking methods significantly increases the efficiency and performance of the machine for various applications.

Automatic Baking (Without Baker)

In the automatic baking method using the tunnel machine, the process of spreading, shaping, and transferring the dough to the baking bed is carried out completely automatically and without manual intervention by the dough sheeter. At the beginning of the baking tunnel, a dough sheeter (dough divider or spreader) is placed according to the type of bread produced to spread the dough evenly and with the desired thickness and, if necessary, shape it into various shapes, such as round or a special mold, then the dough is transferred to the baking tunnel and the baking process begins.

After the baking process is completed, the breads are cut to the desired sizes at the end of the tunnel by the installed cutter and transferred to the special stainless steel basket located at the end of the tunnel.

It is recommended to use cooling belts equipped with a fan and inverter after the baking tunnel. These belts transfer the baked breads to the cooling belt evenly for cooling. This process, in addition to maintaining the quality and freshness of the baked products, helps facilitate their transfer to the packaging stage and optimizes the entire production process.

Semi-Automatic or Manual Baking

In the semi-automatic or manual baking method using the tunnel machine, the spreading, shaping, and transferring of the dough to the baking tunnel is usually done by human labor, which is called a baker. The baker prepares the dough and after dividing it into pieces and letting it rest, spreads the dough and finally transfers it to the baking tunnel. After the baking process is completed, the breads are transferred to the special stainless steel bread collection basket installed at the end of the tunnel.

To increase efficiency and production capacity, in the tunnel machines of Mashhad Baking Industries, it is recommended that when using the tunnel machine in semi-automatic or manual mode, the tunnel machine be ordered with a larger width. This not only provides more space for the baker to work but also allows more bread to be placed on the baking bed at each stage and, as a result, improves the efficiency of the baking process.

The tunnel baking oven uses a 100% indirect heating system for baking products, which is specially designed and patented by Mashhad Baking Industries. In this heating system, two special heat exchangers are used to transfer the heat generated in the combustion chamber to the top and bottom of the baking belt and also to the surface of the bread. In this way, through uniform radiation on the bread and in proximity to the baking belt, the final product is baked completely evenly from top to bottom in a completely hygienic environment using two thermal methods: radiation and proximity.

Among the outstanding features of the indirect heating system are the significant reduction in fuel consumption and the prevention of contamination of the baking area and work environment. The tunnel bread baking machine needs two burners to generate heat. The fuel required for the burner, depending on the customer's needs and the common fuel in the region, can be gas, diesel, or oil. If required by the customer, Mashhad Baking Industries is able to produce the tunnel oven completely electrically.

Control and

Heating System

All control operations of the tunnel oven are performed by an electronic panel installed in the electrical panel. Using the existing control keys, the operator can make settings such as: adjusting the belt and cutter speed, controlling the tunnel temperature, adjusting the temperature of the top and bottom burners, bread cutting size, automatic shutdown of the machine, and selecting predefined programs for baking various breads.

Displaying temperature change curves, the possibility of storing information, the number of breads cut, and transferring via USB, as well as the ability to connect the device to computer systems and the possibility of controlling and adjusting it remotely, etc., are possible upon customer request. The electricity required for the tunnel bakery machine is single-phase.

The tunnel baking oven uses a 100% indirect heating system for baking products, which is specially designed and patented by Mashhad Baking Industries. In this heating system, two special heat exchangers are used to transfer the heat generated in the combustion chamber to the top and bottom of the baking belt and also to the surface of the bread. In this way, through uniform radiation on the bread and in proximity to the baking belt, the final product is baked completely evenly from top to bottom in a completely hygienic environment using two thermal methods: radiation and proximity.

Among the outstanding features of the indirect heating system are the significant reduction in fuel consumption and the prevention of contamination of the baking area and work environment. The tunnel bread baking machine needs two burners to generate heat. The fuel required for the burner, depending on the customer's needs and the common fuel in the region, can be gas, diesel, or oil. If required by the customer, Mashhad Baking Industries is able to produce the tunnel oven completely electrically.

Control and

Heating System

All control operations of the tunnel oven are performed by an electronic panel installed in the electrical panel. Using the existing control keys, the operator can make settings such as: adjusting the belt and cutter speed, controlling the tunnel temperature, adjusting the temperature of the top and bottom burners, bread cutting size, automatic shutdown of the machine, and selecting predefined programs for baking various breads.

Displaying temperature change curves, the possibility of storing information, the number of breads cut, and transferring via USB, as well as the ability to connect the device to computer systems and the possibility of controlling and adjusting it remotely, etc., are possible upon customer request. The electricity required for the tunnel bakery machine is single-phase.

Equipped with

Electric Cutter

In automatic mode, the tunnel machine is equipped with an electric cutter, which is responsible for cutting the bread to the desired sizes. This cutter is installed at the end of the baking tunnel and is controlled by a separate motor and inverter to provide precise settings for the cutting size. The cutter blade is made of stainless steel to provide the highest cutting accuracy and quality and achieve a high-quality and uniform result.

Advantages of the Tunnel Bakery Machine

- Adjustable temperature and baking time

- High production efficiency

- Reduced manual intervention

- Completely hygienic environment

- Optimized fuel consumption

- Prevents the environment from heating up

- Reduces bread waste

- Saves energy costs

- Exports to more than 47 countries worldwide

- Baking uniform and high-quality products

Features of the Tunnel Bakery Machine

- Use of 100% indirect heat

- Emergency stop

- Beautiful and efficient design

- Cutter or blade guard

- Variety in size and model

- Complete insulation

- Cutting and packaging bread in completely desired sizes

- Has up-to-date world standards

- Use of special food-grade steel and the best and latest raw materials in product manufacturing

- Use of advanced digital control system

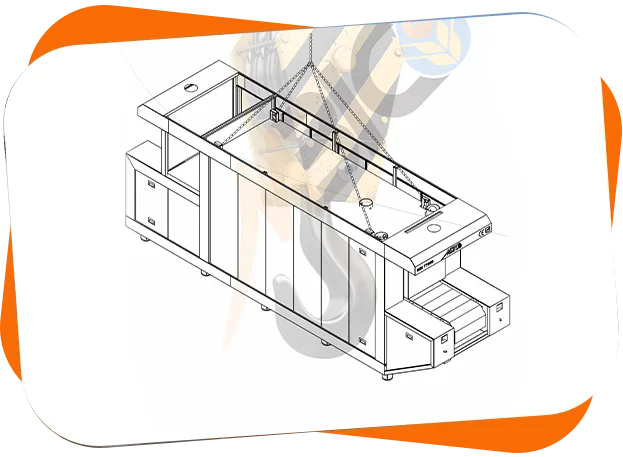

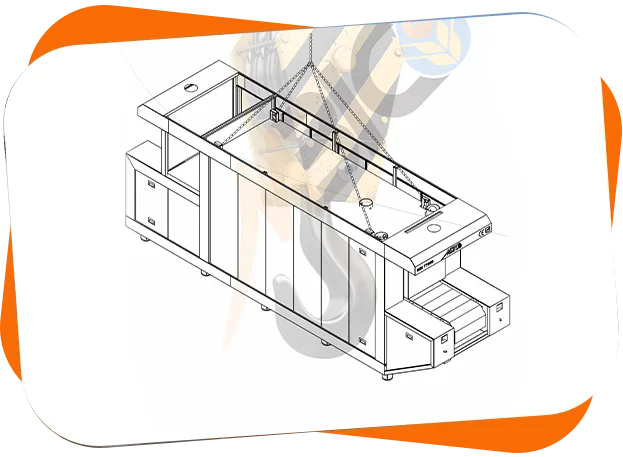

Packaging and Shipping of the Tunnel Bakery Machine

After production, the tunnel bread baking machine is carefully inspected by the quality control unit to ensure that all necessary standards are met and the product is delivered to valued customers without any defects. For the convenience of customers, Mashhad Baking Industries has collaborated with reputable transportation companies to ensure that loading and shipping of products are carried out in the best way for customers.

In order to maintain safety and prevent damage to the structure of the tunnel machine, its movement must be done vertically. In this regard, special hooks are provided in the upper part of the tunnel machine

Installation and Setup of the Tunnel Bakery Machine

For the installation and setup of the tunnel bakery machine, experienced technicians from Mashhad Baking Industries, in coordination with the company's after-sales service unit, will provide the necessary services. These services are provided free of charge to ensure that the tunnel oven is installed and set up in the best possible way at your location.

After the technician arrives on-site and installs the tunnel machine, the necessary training on proper use and maintenance of the baking machine will be provided to you. This training will help you maintain the optimal performance of the tunnel machine and confidently use your baking oven independently, and by utilizing all the capabilities and features of the machine, achieve the best performance and results in your product production. In addition, after installation, the technician performs an initial baking test to ensure that the machine is working correctly and that the production results match your needs.

Warranty and After-Sales Service of the Tunnel Oven

The tunnel machine offered by Mashhad Baking Industries has a one-year warranty. This warranty means guaranteeing the quality and correct operation of the machine during this period and assures you that you are using a baking machine with quality and reliable performance.

In addition to the one-year warranty, lifetime after-sales service will also be provided to you so that whenever you need repairs, adjustments, or consultation, our after-sales service unit is ready to provide services. After-sales service demonstrates our commitment and focus on the satisfaction of our valued customers. We want to provide continuous and professional support to our customers throughout the life of the baking machine so that they can benefit from the performance and efficiency of their machine and have a confident and enjoyable experience using our products.

Places and Businesses Using the Tunnel Baking Machine

The variety in models and dimensions of the tunnel baking oven allows users to benefit from this machine according to the available space, type of application, and required production capacity.

Bakeries and Industrial Bread Complexes: By using the automatic tunnel bakery machine, bakers have the ability to produce high-quality traditional breads in large capacities. The tunnel machine, without manual intervention, while preserving the taste and authenticity of traditional breads, makes it possible to offer soft and dry bread in packaged form.

Specific Locations and Applications: Due to the advanced control system, the tunnel baking oven, as a multi-purpose tool, can be used not only in bread production but also in various other fields. Applications include pencil drying oven, tunnel oven for par-baking pizza dough, and other related activities in various industries.

Iranians Living Abroad: Using the tunnel bread baking machine, Iranian bakers living abroad can bake Iranian breads automatically and without the need for skilled labor and manual intervention, while preserving the same original taste and flavor.

Standards and Certificates of the Tunnel Baking Machine

Complying with up-to-date world standards in the design and manufacture of the tunnel oven, as well as using high-quality and resistant raw materials, ensures that this baking machine has a long life and maintains its optimal performance over time, and ultimately creates user trust and provides high-quality products. Standards, certificates, and technical regulations in the tunnel baking machine are determined to ensure its quality, safety, and optimal performance.

Iranian National Standard

ISO 9001 Certificate

GOST Russia Certificate

CE Europe Certificate

CSA Canada Certificate

UL Canada Certificate

Models and Technical Specifications of the Tunnel Baking Machine

At Mashhad Baking Industries, the indirect heating tunnel machine is known as the "7800 Tunnel Machine." In order to provide the best performance and results for customers, this baking machine is designed and produced in very diverse dimensions and models according to production capacity, customer needs, and the type of bread produced. This variety in dimensions and settings of tunnel machines allows customers to choose the appropriate machine based on their needs and production capacity.

Model

Dimensions (cm)

belt width 50

belt width 80

100 belt width

Voltage (V)

Motor Power (kW)

Belt Material

Fuel Type

Fuel Consumption (per ton)

Baking Capacity in 8 Hours (kg)

MBI D COMBO 7800 CI/CS/CIP 400

belt width 50: 410*124*400

belt width 80: 195*160*400

belt width 100: -

Voltage (V): 220

1.1-2.2

Steel/Galvanized/Cast Iron/Steel

Gas/Diesel/Electric

Fuel Consumption (per ton) 50M-46.7L

Baking Capacity in 8 Hours (kg): 800-1300Kg

MBI D COMBO 7800 CI/CS/CIP/CCIK 500

belt width 50: 195*124*500

belt width 80: 195*160*500

belt width 100: -

Voltage (V): 220

1.1-2.2

Steel/Galvanized/Cast Iron/Steel

Gas/Diesel/Electric

Fuel Consumption (per ton) 50M-46.7L

Baking Capacity in 8 Hours (kg): 1000-1500Kg

MBI D COMBO 7800 CI/CS/CIP/CCIK 600

belt width 50: 195*124*600

belt width 80: 195*160*600

belt width 100: 195*160*600

Voltage (V): 220

1.1-2.2

Steel/Galvanized/Cast Iron/Steel

Gas/Diesel/Electric

Fuel Consumption (per ton) 50M-46.7L

Baking Capacity in 8 Hours (kg): 1200-2000Kg

- For maintaining bread moisture and softness, shorter tunnel machines will be suitable.

- If you need to bake dry breads, use a longer tunnel machine.

- To increase production capacity, use a tunnel machine with multi-row baking capability.

- For maintaining bread moisture and softness, shorter tunnel machines will be suitable.

- If you need to bake dry breads, use a longer tunnel machine.

- To increase production capacity, use a tunnel machine with multi-row baking capability.

Frequently Asked Questions about the Tunnel Baking Machine

- High-capacity product baking

- Baking bread in a completely hygienic environment

- Complete and proper insulation of the tunnel machine

- Optimized fuel consumption and 100% indirect heating system

- Automatic baking and packaging of bread without manual intervention

The tunnel machine has a 100% indirect heating system.

Tunnel machines are produced in very diverse sizes that customers can use based on their production capacity. In general, tunnel machines have a high production capacity, and you can use wide tunnels for two- and three-row baking to increase production capacity in automatic lines.

Various traditional breads such as completely soft Lavash bread, Barbari bread, Taftoon bread, dry bread, Sangak bread, par-baking pizza dough, pencil drying, and other specific applications.

For baking completely soft Lavash bread and Tehran Lavash, a 4-meter tunnel machine with a 50 cm belt width is recommended.

The tunnel oven is produced in two models: fully automatic baking machine and semi-automatic baking machine, and according to the type of product to be produced in different dimensions and with the technical specification Tunnel 7800 at Mashhad Baking Industries. The tunnel oven in terms of baking tunnel length in four models: 4-meter tunnel machine, 5-meter tunnel machine, 6-meter tunnel machine, 8-meter tunnel machine and in terms of baking belt width: single-row tunnel bakery machine, two-row tunnel bakery machine, three-row tunnel bakery machine.

For fully automatic baking of Barbari bread, a 6-meter tunnel machine with an 80 cm belt width is recommended.

One-year warranty - Lifetime after-sales service.

This time can vary depending on the number of orders waiting in the production queue. You can contact our experts for more information.

For baking dry bread, a 6-meter tunnel machine with a 50 or 80 cm belt width is recommended for single- or double-row baking (according to the required baking capacity).

Yes, the tunnel baking machine, due to having the latest world standards and using the best raw materials in manufacturing and the ability of automatic bread baking, is completely suitable for export. We are proud to announce that we have exported this product to more than 46 countries worldwide.

For fully automatic Taftoon bread baking, a 4-meter tunnel machine with a 50 cm belt width is recommended.

-

The tunnel oven is known by various names among its users, including:

- Tunnel Oven

- Tunnel Bakery

- Tunnel Baking Machine

- Indirect Heat Tunnel

- Automatic Bakery Machine

- Automatic and Semi-Automatic Tunnel Machine

- Automatic Indirect Heat Tunnel Machine

For fully automatic baking of Sangak bread, a 5-meter tunnel machine with a 50 cm belt width is recommended.

Pricing of the Tunnel Bakery Machine

Due to the wide variety of tunnel machine models and the importance of choosing the best tunnel baking machine based on your needs, you can contact our sales experts through the provided communication channels for detailed consultation and information on the tunnel machine price. Our sales team is ready to provide information and guidance to assist you in choosing the best tunnel baking machine and receiving complete information about prices and technical specifications.

Online chat

7*24

We are ready to assist you

In-person visit.

Factory: Kilometer 22, Asiayi Highway, Beginning of Mohammadabad Qaim Maqam Road, Mashhad

Head Office: No. 579, Molk al-Shu'ara Bahar Street, Between Bahar 12 and 14, Mashhad

Phone contact

Factory:

+985132464090

Office:

+985138583180

Email:

To receive advice and contact our sales experts, please send your request via email.

mbi@mbico.com