Automatic Production Line for Baking Sangak Bread

Sangak bread, a traditional Persian flatbread, is known for its distinctive texture, crispy crust, and unique shape. Traditionally baked in stone ovens, the process of making Sangak bread requires skill and precision. However, with the advancement of bakery machines, modern bakeries can now produce high-quality Sangak bread efficiently and consistently using an Automatic Production Line for Baking Sangak Bread.

This automated system streamlines every step of the baking process, from dough preparation to final baking, ensuring uniformity, efficiency, and high production capacity. By incorporating cutting-edge baking ovens and advanced bakery technologies, this production line maintains the authenticity of traditional Sangak bread while optimizing operations for large-scale manufacturing.

Introduction to the Automatic Sangak Bread Baking Machine

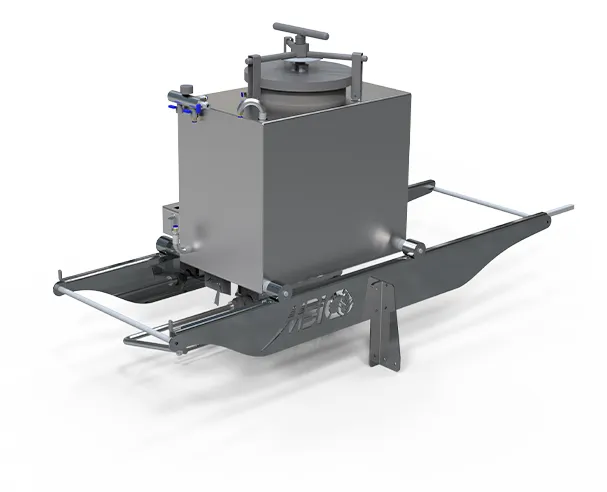

The Portable Rotary Automatic Sangak Bread Baking Machine consists of an advanced rotary baking unit and specialized equipment designed specifically for baking Sangak bread. This machine enables the automatic production of Sangak bread with ease and efficiency. Recognized as one of the best-selling automatic Sangak bread baking machines, it is a popular choice among bakeries. Below is a description of its various components:

Introduction to the Portable Rotary Baking Machine

The Portable Rotary Sangak Baking Machine is a baking system equipped with a 100% indirect heating mechanism, complete insulation, and compliance with international standards. This bakery machine has successfully met all the requirements of bakers for producing traditional Iranian Sangak bread and is recognized as an excellent alternative to the traditional Sangak oven. The Portable Rotary Sangak Machine is capable of producing traditional Sangak bread with superior quality and high performance.

The Portable Rotary Automatic Sangak Baking Machine offers an exceptional experience in producing Sangak bread with outstanding flavor, unique structure, and long-lasting freshness. This machine is designed to bake Sangak bread evenly while retaining its internal moisture. The result of this process is the production of Sangak bread with a golden crust, soft texture, and authentic aroma and taste. As its name suggests, the portable rotary design allows for easy transportation, enabling bakers to relocate their businesses without the damage or challenges often associated with traditional bakery equipment. This feature ensures the continuous production of high-quality traditional Sangak bread in any location with ease and reliability.

The comprehensive and well-engineered insulation of the Portable Rotary Sangak Baking Machine plays a crucial role in reducing fuel consumption, enhancing energy efficiency, and maintaining the quality of bread baking. It can reduce fuel consumption by up to three times. Additionally, it significantly improves the prevention of environmental overheating. By preventing heat leakage and creating effective thermal insulation, it avoids unauthorized heat dissipation into the surrounding environment, ensuring a more efficient and safer workspace for users.

Introduction to the Sangak Mixer Machine

The Sangak Dough Mixer, also known as the Sangak Dough Kneader, is an essential and vital tool for the automatic production of Sangak bread. It enables the preparation of high-viscosity dough in the shortest possible time, helping bakers work with greater speed and efficiency in the dough preparation process.

The specialized Sangak dough mixer is equipped with two bowls, each with a capacity of 120 kilograms of dough. One bowl is used as the main bowl for dough preparation, while the other is designated for dough storage and resting. This system helps bakers optimize the dough preparation process, producing higher-quality Sangak dough more effectively.

A standout feature of this Sangak mixer is its detachable bowl, which reduces manual intervention in the bread production process. Additionally, the Sangak dough mixer is equipped with an inverter and offers two different speed settings, accelerating the kneading process and allowing bakers to prepare dough efficiently in less time.

Introduction to the Sangak Dough Lifter Machine

The Sangak Dough Lifter Machine is designed to increase ease of operation and reduce manual intervention, and it is mounted on the body of the baking machine. The dough bowl is placed on the lift’s base, and then the baker uses a remote control to guide the dough bowl toward the Sangak dough depositor, allowing the dough to be discharged into the depositor.

The primary function of the Sangak dough lifter machine is to move the dough bowl, tilt it, and transfer the dough into the deposit tank. This process is carried out efficiently without direct hand involvement, enhancing both hygiene and operational speed.

Introduction to the Dough Depositor, Automatic Sangak Baker

The Automatic Sangak Baker is a dough depositor equipped with a dough reservoir and designed for spreading and transferring Sangak dough onto the baking surface. This machine is also known as the "Sangak Depositor" or "Sangak Dough Spreader" and is installed at the opening of the rotary baking machine.

To prevent excessive fermentation, preserve dough quality, and improve the bread produced, the body of this machine is designed with a double wall, allowing water circulation within. This smart design helps the dough depositor maintain optimal thermal conditions for baking the dough, ensuring the bread's quality and preventing undesirable fermentation.

The dough depositor is equipped with an air compressor to transfer dough from its reservoir to the baking surface. The compressor, using filtered air pressure, transfers the dough evenly while maintaining its structure and quality, ensuring that the produced bread has a desirable texture and high quality. Another notable feature of the Sangak dough depositor is the sesame sprinkling system, which allows for precise control over the amount of sesame sprinkled onto the Sangak bread.

Finally, after passing through the above stages, the Sangak dough is baked in the rotary baking machine in a completely hygienic environment with a 100% indirect heating system. Stainless steel blades are placed between the cast iron plates of the portable rotary baking machine, and when the dough falls onto them, the bread is automatically cut and prepared for the next steps. At this stage, human intervention is required to transfer the baked bread from the baking machine to the cooling and collection phase.

Heating System of the Portable Rotary Automatic Sangak Machine

The Portable Rotary Automatic Sangak Baking Machine utilizes a 100% indirect heating system, specially designed and patented by Mashhad Baking Industries. In this system, heat generated in the combustion chamber is fully isolated and directed to the underside of the baking plates as well as the top surface of the Sangak bread through a specialized heat exchanger. As a result, the bread is baked evenly from both the top and bottom in a completely hygienic environment using two thermal methods: radiant and adjacent heat.

The indirect nature of the heating system reduces fuel consumption by 50%, prevents contamination of the baking surface and work environment, and avoids heating the surrounding area, ensuring comfort for users. The portable rotary baking oven requires two burners to generate heat. The fuel used for the burners can be gas, diesel, or oil, depending on the customer's needs and the commonly available fuel in the region.

Baking Surface of the Portable Automatic Sangak Machine

The baking surface of the Sangak machine is a key factor in determining the final quality of the Sangak bread. The proper selection of the material and type of baking surface directly impacts the uniformity and quality of the baking process. In the Portable Rotary Automatic Sangak Machine, a cast iron surface shaped like pebbles is used, which is the most suitable type of surface for Sangak bread.

Cast iron, with its ability to retain and evenly distribute heat, improves the baking process and produces Sangak bread with a desirable and consistent texture. The indentations and protrusions created by the cast iron surface contribute to the unique appearance and texture of the Sangak bread, making it distinct. Stainless steel blades are designed between the cast iron surfaces so that when the dough falls onto them, the Sangak bread is automatically cut and shaped.

Key Features of the Automatic Sangak Bread Production Line

The Automatic Production Line for Baking Sangak Bread is designed with state-of-the-art technology to deliver superior performance and efficiency. Below are some of its standout features:

- Automated Dough Preparation: Ensures precise ingredient mixing and uniform dough consistency.

- High-Precision Dough Sheeting System: Creates the perfect thin and even dough layer, mimicking traditional hand-stretched techniques.

- Advanced Baking Ovens: Utilizes controlled temperature settings for optimal baking results, enhancing the bread’s texture and taste.

- Continuous Production System: Minimizes downtime and maximizes output, ideal for high-demand bakeries.

- User-Friendly Control Panel: Allows easy adjustments to baking parameters for customized bread quality.

- Energy-Efficient Design: Reduces power consumption while maintaining high productivity levels.

- Durable and Hygienic Construction: Made from food-grade stainless steel to ensure safety and longevity.

Models and Technical Specifications of the Portable Automatic Sangak Machine

At Mashhad Baking Industries Company, the Portable Rotary Automatic Sangak Machine is designed and manufactured in two different sizes based on the production capacity required by customers. The automatic Sangak machine is built with the aim of providing optimal solutions for producing high-quality Sangak bread, tailored to meet the diverse needs of customers.

MBI DP 270 80 CIK

Dimensions: 265*257*266

Voltage (Volts): 220

Motor Power (Kilowatts): 0.75 Kilowatt

Type of Cast Iron Plate: Pebbled (Textured)

Cast Iron Plate Length: 80cm

Gas/Gasoline

Fuel Consumption: 50M-46.7L

Number of Operators Needed: 2

Baking Capacity in 8 Hours: 900-1100kg

MBI DP 320 85 CIK

Dimensions: 265*320*340

Voltage (Volts): 220

Motor Power (Kilowatts): 0.75 Kilowatt

Type of Cast Iron Plate: Pebbled (Textured)

Cast Iron Plate Length: 85cm

Gas/Gasoline

Fuel Consumption: 50M-46.7L

Number of Operators Needed: 2

Baking Capacity in 8 Hours: 900-1100kg

Standards and Certifications of the Automatic Portable Rotary Sangak Machine

Compliance with modern global standards in the design and construction of the fully automatic portable rotary Sangak machine, along with the use of high-quality and durable materials, ensures the machine's longevity and maintains its optimal performance over time.

Iranian National Standard

ISO 9001 Certificate

GOST Certificate of Russia

CE European Certificate

Canadian CSA Certificate

UL Certification Canada

Advantages of the Automatic Rotary Sangak Bread Machine

- Reduction of bread waste

- Prevention of ambient overheating

- High production efficiency

- Baking of exceptionally high-quality products

- Exported to over 46 countries worldwide

- Up to threefold reduction in fuel consumption

- Fully hygienic platform for bread production

- Reduced labor requirements

- preserving the quality and authentic taste of Sangak bread

Features of the Automatic Rotary Sangak Bread Machine

- Easy portability and relocation

- Complete insulation

- Elegant and efficient design

- Utilization of 100% indirect heating (IGF)

- Compliance with modern global standards

- Advanced digital control system

- Use of the finest and most modern raw materials in construction

- Adjustable temperature and baking time

- Use of various stainless steels designed for the food industry

Installation and Setup of the Fully Automatic Sangak Bread Machine.

The semi-automatic portable rotary Sangak machine is installed and set up free of charge by experienced technicians from the after-sales service team. The technician will guide you through the installation process, initial settings, proper usage of the machine, maintenance, and after-sales services. This ensures that you can independently use the machine efficiently and achieve the best results in baking traditional Sangak bread by fully utilizing all the capabilities and advantages of the portable rotary Sangak machine.

Warranty and After-Sales Service for the Automatic Sangak Bread Machine

The portable rotary indirect heating Sangak bread machine, with its unique features and capabilities, has become the best alternative to traditional Sangak ovens for baking Sangak bread and is exported to other countries around the world. The automatic portable rotary Sangak bread machine comes with a 12-month warranty and lifetime after-sales service. This warranty reflects the manufacturer's commitment to providing high-quality performance, and in the event of any malfunction or issue, customers can take advantage of free repair and replacement services for consumable parts.

Comparison of the Automatic Sangak Machine with the Traditional Sangak Oven

Automatic baking

Uniform baking

Advanced control system

Reduction of manual intervention

The unique features of the automatic rotary bakery machine for Sangak compared to the traditional Sangak oven are:

Mass production

Hygiene and safety

Time and energy savings

Reduction in manpower

Frequently Asked Questions about the Portable Rotary Automatic Sangak Machine.

Depending on the customer's needs and the local fuel type, it can be either gas, diesel, or oil.

Yes, the portable rotary automatic sangak machine, due to its use of the latest global standards and automatic baking process, is one of the best-selling sangak baking machines for export. This machine allows Iranians living abroad and others to enjoy the taste and flavor of traditional sangak bread.

Stainless steel blades are placed between the cast iron plates of the automatic rotary sangak machine. When the dough is poured onto the cast iron surface by the dough dispenser, these blades automatically cut the bread at specified locations.

The heating system in the automatic rotary sangak machine is completely indirect.

The baking surface of the automatic rotary sangak machine is made of elevated cast iron, which helps maintain the traditional form of sangak bread. One of the advantages of using this machine is the hygienic baking process and the production of sangak bread.

Yes, the body of the automatic sangak dough spreader or shater is equipped with a sesame sprayer, which automatically spreads sesame on the bread after the dough is spread on the cast iron surface.

One-year warranty - Lifetime after-sales service.

The baking capacity of this automatic portable Sangak bakery machine per 8-hour work shift is as follows:

MBI DP 270 produces 700-900 kilograms of baked bread

MBI DP 320 produces 900-1100 kilograms of baked bread

Uniform product baking

Baking variety in this device

Low and optimized fuel consumption

Baking with 100% indirect heat

Single burner design and complete insulation of the device

Ability to control steam from dough water evaporation due to the design of the baking chamber

Option to build the oven in two or three pieces for spaces with small or limited entrances

Fortunately, yes. Pakt Industries Mashhad prepares the sangak baking machine in a two-piece or even three-piece configuration for its customers. The 320 size of this product is typically produced in a two-piece design for easy transport and mobility.

Yes, by adjusting the cutting blades installed between the cast iron plates, the length of the sangak bread can be adjusted and cut according to the desired size.

Price of the fully automatic sangak baking machine.

For information about the price of the fully automatic sangak bakery machine, to get acquainted with the different models of the sangak machine, to learn about the purchasing conditions directly from the factory, and to receive pre-purchase consultation, you can contact our sales experts through the communication channels below:

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com