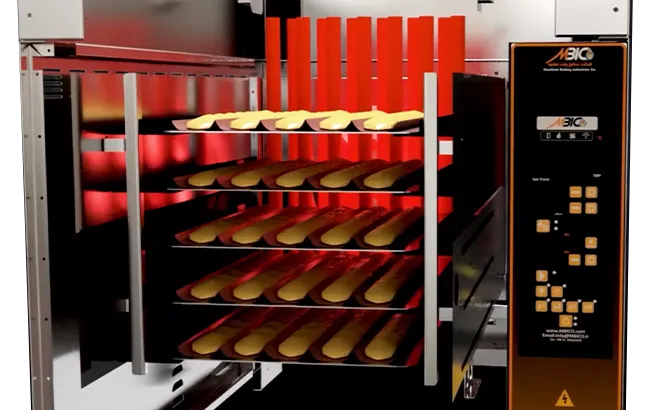

Convection Oven

Homogeneous & Good Uniformity of Baking, Equipped with Steam System & Hot Air Circulation, Provided with Separate Fermentation Chamber. Convection Ovens are particularly suitable for baking any type of Bread, Pastry Products, Pizza, Strudel & Cooking Food; this Oven is perfectly useful for Confectioners, Restaurants and Hotels.

The Convection Oven from MBIco is a modern mini oven with a wide range of capabilities. The convection oven is an excellent choice for starting a business, bakeries, restaurants, fast food outlets, catering services, cooking schools, and even home use. It is perfectly suited for baking various types of pastries, cakes, leavened breads, and a variety of foods such as chicken, fish, kebabs, and pizzas.

The convection oven is a practical and unique baking appliance that can meet the needs of various businesses. It is ideal for baking restaurant and fast food items, as well as preparing a wide range of pastries and breads. The convection oven is an excellent choice for starting a small-scale business or product production. One of the greatest advantages of the convection oven is its versatility in baking products. It can produce a variety of pastries, cakes, leavened breads, and diverse foods such as chicken, kebabs, pizzas, and more, all with the best baking quality.

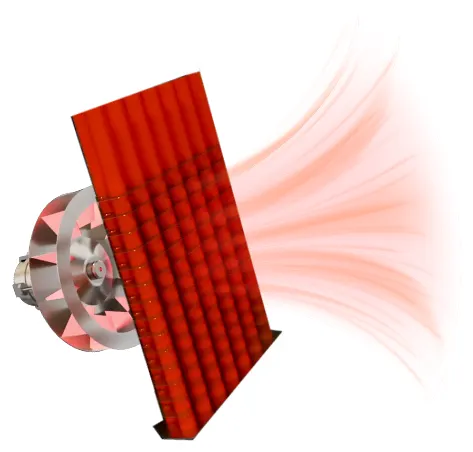

The convection system ensures even temperature distribution, resulting in faster cooking times.

"Convection" is a new feature that ensures even heat distribution inside the oven. This feature consists of a powerful fan, shaped like a propeller, which is specifically installed at the back of the oven to regulate and maintain uniform temperature during the cooking process. Ovens equipped with convection capabilities provide better and more efficient cooking, resulting in food being cooked more evenly, accurately, and faster.

It is produced with Electricity and Gas. It can be provided as 5 & 10 Pieces Tray Capacity. Variety of Baking Different Sort of Products. Steam distribution on the Baking Chamber is obtained by means of Steam Generator System that leads to Perfect Baking. At the bottom of the Convection Oven, there is a Fermentation Chamber that provides Heat and Steam for Baking Bulk and Yeast Breads. This Oven has a very good uniformity of Baking and Energy Saving due to High Quality Insulation.

Separate fermentation chamber as a complement to convection ovens.

The convection oven consists of two parts: the baking chamber and the fermentation chamber.

The baking chamber of the convection oven, also known as the baking cabin, is equipped with steam injection, allowing steam to be introduced into the product during the baking process. This enhances the product's baking process. The convection baking cabin is equipped with tempered glass and a lighting lamp to provide users with a clear view of the product while it's baking.

FERMENTATION

CHAMBER

The fermentation chamber of the convection oven, also known as the fermentation room, is designed at the lower part of the oven and is used for the fermentation process of dough. It enables easy baking of large loaves of bread and products that require steam. Therefore, this oven can be used as a small bakery device for baking fancy bread. The fermentation chamber is designed to be separable from the baking chamber, and if the customer does not require this feature, the convection oven can be produced without the fermentation chamber.

Heating system of the convection oven

The heat distribution in the convection oven occurs entirely indirectly through the circulation of warm air by the built-in fans. These fans have a special design and operate with very high efficiency. Due to the internal fans, the convection oven is also known as a "fan oven" or "air circulation oven." The high-quality baking results are a consequence of the advanced heating system and excellent heat distribution in convection ovens.

Control system of the convection oven

In the convection oven, all control operations are carried out by a precise and advanced electronic control panel, specifically designed for this oven by MBICO. Through this control system, necessary settings such as motor speed, temperature, automatic shutdown time, and baking time timer are managed, allowing the operator to execute preset programs for baking.

The convection oven, due to its complete insulation and high efficiency, has a very low fuel consumption, which in turn reduces production costs, giving the final product a greater competitive advantage. The mini convection oven is designed with the capability to heat up quickly, allowing you to save time during the baking process.

Models and specifications of various convection ovens.

The convection oven of Mashhad Baking Industries is designed and produced in two models: gas convection oven and electric convection oven, and in two capacities: 5 trays and 10 trays. The convection oven is equipped with a fermentation chamber or room, which can be produced according to customer orders. The variety in models and capacities of the convection oven allows users to choose the oven according to their needs in any environment. The convection oven can be used as an industrial baking oven in workshops and production units, or as a domestic oven for home use, allowing users to benefit from its diverse features and capabilities for baking various products.

10-tray convection oven

The 10-tray convection oven, as the name suggests, has 10 levels and 10 trays with dimensions of 60×40 cm. The fermentation chamber of this oven also has a capacity of 10 trays with dimensions of 60×40 cm. With its high capacity, this oven is an ideal option for use in industrial and large-scale production environments. Therefore, the 10-tray convection oven is recognized as an industrial convection oven in the market and is used for professional applications.

5-Tray Convection Oven

The 5-Tray Convection Oven, as the name suggests, has 5 trays, each with dimensions of 60×40 cm. The fermentation chamber of this oven also has a capacity equivalent to 5 trays of the same size. This oven can be an ideal option for starting a business, entrepreneurship, setting up small workshops, home-based businesses, baking schools, and small-scale production. For this reason, it is commonly used as a semi-industrial or workshop convection oven.

Locations and professions where convection ovens are used:

The convection oven, due to its versatility in cooking, multifunctionality, and other advantages, has special applications in many fields.

Hotels | Cafes | Catering services | Restaurants | Fast food outlets | Hospitals | Hypermarkets | Culinary schools | Food production facilities | Owners of pastry and confectionery businesses | Bakeries and pastry workshops with a wide variety of products | Establishing home-based and small-scale businesses.

Advantages of the Mini Convection Oven

- Baking products with the highest quality

- Fast and even baking

- Completely optimized fuel consumption

- Variety in product baking

- Ability to produce diverse products

- Uniform heat distribution

- Advanced heating system and excellent heat distribution

- Quick preheating for immediate use

- Stainless steel body and interior baking chamber, specially designed for the food industry

- One-year warranty and lifetime after-sales service

- Suitable for use in pastry shops, bakeries, restaurants, fast foods, hotels, hypermarkets, catering facilities, hospitals

Features of the Mini Convection Oven

- Complete insulation

- Equipped with four wheels for easy transport and movement

- Equipped with a blowing fan

- Digital control system

- Hot air circulation system

- Equipped with a steam chamber (Fermentation)

- Equipped with a lighting system

- Available in both gas and electric types

- Equipped with a steam system

- Customizable convection oven based on customer needs

- equipped with the latest global standards

Transportation and delivery of gas and electric convection ovens

For the safe transportation and relocation of the convection oven, you can use a forklift. When moving the convection oven with a forklift, it is important to move the oven vertically to protect its internal and external structure from potential damage. To do this, lift the oven from the side using the forklift’s long forks and transfer it to the desired location.

The convection oven, also known as a "blower oven," is equipped with four wheels for easier movement. Two of these wheels, one at the front and one at the back, are equipped with a braking system. By pressing the brake pedal, unwanted movement is prevented, and the oven is secured in place. When shipping the convection oven, four handles are provided for easier relocation. By attaching these handles to the four corners of the oven’s outer walls, you can easily move the oven and take advantage of the more convenient transportation options for this oven.

Standards and Certifications of Convection Oven

Adhering to the latest global standards in the design and manufacture of gas and electric convection ovens, as well as using high-quality and durable raw materials, ensures that this cooking device has a long lifespan and maintains its optimal performance over time, ultimately building user trust and delivering high-quality products. Standards, certifications, and technical regulations for gas and electric convection ovens are established to ensure their quality, safety, and optimal performance.

Iran National Standard

ISO 9001 Certification

GOST Certification Russia

CE Certification Europe

CSA Certification Canada

UL Certification Canada

Convection OVEN FAQs

دستگاه پخت کانوکشن در دو مدل: فر پخت کانوکشن گازی و برقی و در دو سایز 5 سینی و 10 سینی طراحی و تولید می گردد.

Convection ovens can be used to bake a wide range of products, including large loaves of bread, various types of pastries and cakes, as well as savory dishes like pizza, pies, lasagna, chicken, steak, burgers, kebabs, and more.

Heat distribution in convection ovens is achieved through the circulation of hot air by built-in fans. While gas convection ovens require single-phase power, electric convection ovens typically need three-phase power.

Given the various applications of the convection oven, this product is known by different names such as: mini convection oven, gas convection oven (stacked), mini oven for baking fancy bread, home convection oven, industrial gas convection oven, and semi-industrial gas convection oven.

The warranty is one year, and the after-sales service is lifetime.

The convection oven is produced in two versions, with a steam chamber (fermentation) and without it, allowing customers to order according to their needs.

Yes, the convection oven is capable of generating steam during the baking process and is fully suitable for baking bulky products that require steam.

Depending on the number of orders in the production queue, the manufacturing and delivery time for the convection oven may vary. For more accurate information and further details, you can contact our sales experts.

The gas single-phase convection oven operates on a 220-volt power supply and is fully compatible with both natural gas and city electricity.

The electric three-phase convection oven operates on a 380-volt power supply.

Installation and setup of convection ovens is completely free for our valued customers

A convection oven is perfectly suited for use in a wide range of settings, including bakeries, pastry shops, restaurants, fast food establishments, hotels, hypermarkets, catering services, hospitals, cooking schools, and home kitchens.

The price of gas and electric convection ovens

Mashhad Baking Industries, with the aim of providing a reliable, easy, and satisfying shopping experience for valued customers, has established several effective communication methods. To inquire about the price of convection ovens and learn about the purchasing conditions for baking convection ovens, you can use the following communication channels:

Online chat

7*24

We are ready to assist you.

In-person visit

Factory: Km 22, Asian Highway, Beginning of Mohammadabad Qaem-Maqam Road, Mashhad

Head Office: No. 579, Between Bahar 12 and 14, Melikushara Bahar Street, Mashhad

Phone contact

Factory:

+985132464090

Head Office:

+985138583180

To receive consultation and connect with our sales experts, please send your request through the following email:

mbi@mbico.com